Induction Curing Measuring Tape Paint Type:

Induction Curing Measuring Tape Paint Type:

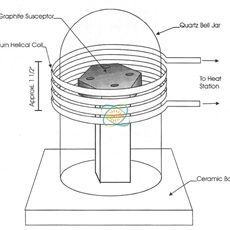

Class: Induction Tempering or PreheatingIntro: Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400F at the rate specified.…

Induction Bonding Solar Panels Type:

Induction Bonding Solar Panels Type:

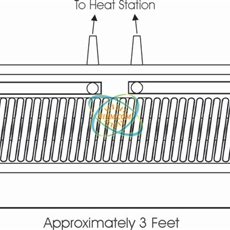

Class: Induction BondingIntro: Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.Material 3″ by 10.25″ section of a 21″ solar panel shingleTemperature 130 CFr…

Induction Bonding Steel Clips Type:

Induction Bonding Steel Clips Type:

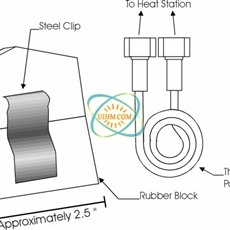

Class: Induction BondingIntro: Objective To heat metal clips and press-bond them into rubber seals. The metal needs to be heated to 250F to 350F with a cycle time not exceeding 3 secondsMaterial Steel clips and rubber sealer blocksTemperature 250F to 350FFrequency 373 kHzEquipment UM-U

Metal to Plastic by Induction Bonding Type:

Metal to Plastic by Induction Bonding Type:

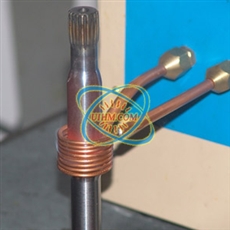

Class: Induction BondingIntro: Objective To heat a steel magnetic steel post to 300F for a bonding application.Material Magnetic steel posts Plastic handleTemperature indicating paintTemperature 300F (149C)Frequency 288 kHzEquipment UM-UHF-6 kW, 100-400 kHz induction heating power supp

Induction Annealing Stress Relieving Type:

Induction Annealing Stress Relieving Type:

Class: HF Induction AnnealingIntro: STRESS RELIEVING,NORMALISING AND ANNEALINGStress RelievingStress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling an

INDUCTION HARDENING AND FLAME HARDENING Type:

INDUCTION HARDENING AND FLAME HARDENING Type:

Class: Induction HardeningIntro: WHAT ARE THE TREATMENTS?Induction hardening and flame hardening are methods for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening effec

Induction HARDENING AND TEMPERING OF TOOLS Type:

Induction HARDENING AND TEMPERING OF TOOLS Type:

Class: Induction HardeningIntro: WHAT ARE THE STEELS?Tool and die steels are covered in BS 4659:1989, although both American nomenclature and a variety oftrade names are also in use. Available in high-quality grades, these specifically-designed steels can be groupedbroadly according to t

Induction De-bonding Stainless Steel Type:

Induction De-bonding Stainless Steel Type:

Class: Induction BondingIntro: Objective To separate bonded stainless steel / carbon fiber assemblies by heating tang, softening the adhesive bondMaterial Stainless steel and carbon fiber insertsTemperature 300 F (149C)Frequency 200 kHzEquipment • UM-UHF-6kW induction heating system, e

Induction Bonding plastic sleeve to stainless steel handle Type:

Induction Bonding plastic sleeve to stainless steel handle Type:

Class: Induction BondingIntro: Objective Heating end of a stainless steel handle with a plastic sleeve coated with heat adhesive for a bonding applicationMaterial 1” (25mm) OD stainless steel handle 0.30” (7.6) thick covered with a plastic sleeve that is coated with a heat adhesive be…

Induction Debond rubber seal from steel Type:

Induction Debond rubber seal from steel Type:

Class: Induction BondingIntro: Objective Debond a fluorocarbon rubber seal from a carbon steel oil seal Material 4” (10.2cm) OD carbon steel oil seal with a fluorocarbon rubber sealTemperature 1200 F (649 C)Frequency 179 kHzEquipment • UM-UHF-6kW induction heating system, equipped wit…

Recommended

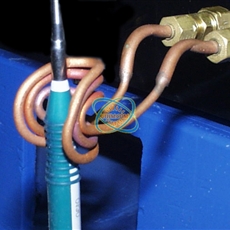

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship