Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled.

Induction Annealing of the material changes physical properties of the material such as strength and hardness.

Features:

- Improved power factor

- Tropicalised design

- Compact size

- Highly adaptable for automation

- Eco-friendly due to noiseless and flameless operation

- No statutory approvals required

- Lesser risk involved compared to conventional methods

- Application Specific

- Uniform annealing with better quality end product

- Lesser Annealing cost comparing to conventional methods

- Faster Annealing cycle

- Higher productivity

- Highest system efficiency

- Auto or manual mode operation

Induction annealing has many benefits. The heat is generated directly in the material, leading to high efficiency and low energy costs. It is also a fast and controllable process, which will improve your throughput. And the heat is very accurate—crucial to meet today's stringent quality standards.

Applications:

- Annealing of Milk Cans, Oxygen cylinder for neck formation.

- Shell Annealing.

- Annealing of wires.

- Continuous Annealing of copper wires.

- Stainless Steel / Aluminum Utensils

- All Cold Formed Steel Components.

- Stress Relieving.

- Post weld Annealing.

- Annealing of Copper tubes.

- Annealing of knife, blade ends.

- Annealing of brazing wires & Rods.

UIHM Induction offers seam annealing of tube welds and full body annealing of both magnetic and non-magnetic tube products. We also provide integrated induction annealing solutions for steel strip and wire production.

The right heat in the right place reforms the material structure and reduces internal stresses in just the way you want.

UIHM induction annealing machines are designed to be used for Normalising, Stress relieving and Process Annealing.

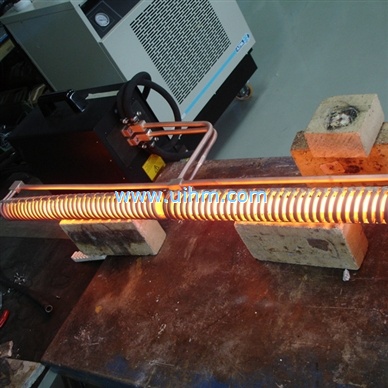

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction annealing SS-Steel knife

induction annealing copper plate

induction heating steel pipe by flexible water cooled induction coil

induction annealing with U shape double ear induction coil

induction annealing steel strip online

induction annealing with large parallel induction coil

induction annealing steel plate by U shape double ear induction coil

induction annealing SS steel plate

induction annealing for SS steel pipe by 200KW induction heater

induction annealing copper bar by flexible induction coil

induction annealing bullet shell

induction annealing for stainless pipe

induction annealing umbrella ribs by 60KW induction heater (UM-60AB-UHF)

induction annealing steel wire online

induction annealing steel umbrella ribs by 40KW induction heater (UM-40AB-HF)

induction annealing by horizontal type induction heater

induction annealing rod steel (steel bar)

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater Type:

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater Type:

Class: HF Induction AnnealingIntro: induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction annealing SS-Steel knife Type:

induction annealing SS-Steel knife Type:

Class: HF Induction AnnealingIntro: induction annealing SS-Steel knife

induction annealing copper plate Type:

induction annealing copper plate Type:

Class: HF Induction AnnealingIntro: induction annealing copper plate