Metal to Plastic by Induction Bonding

Views Send Enquiry

Objective To heat a steel magnetic steel post to 300°F for a bonding application.

Material Magnetic steel posts Plastic handle

Temperature indicating paint

Temperature 300°F (149°C)

Frequency 288 kHz

Equipment Power of 6 kW, 100-400 kHz induction heating power supply, equipped with a remote heat station containing a 0.66 μF capacitor.

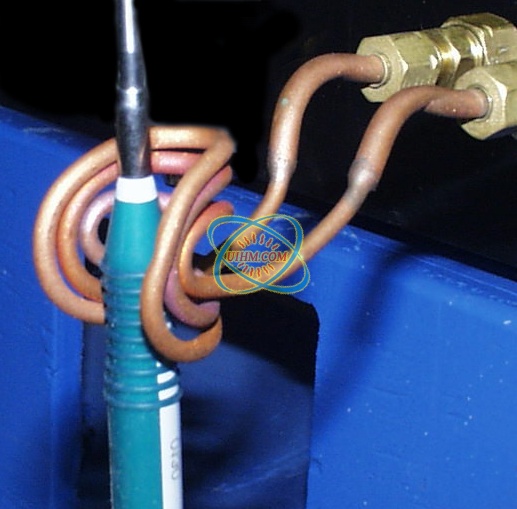

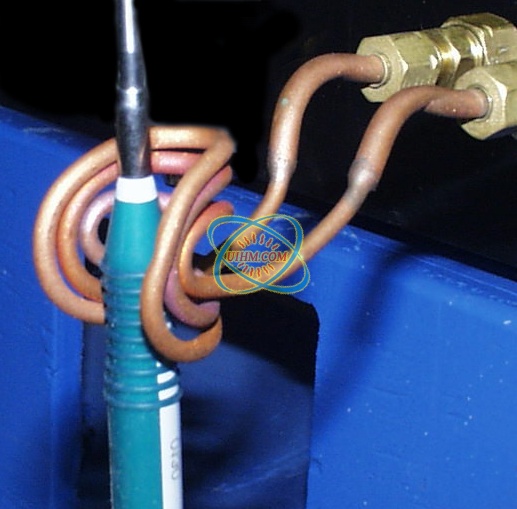

A folded pancake induction heating coil designed and developed specifically for this application.

Process Initial tests were conducted on parts without any plastic

assembly. Temperature indicating paint is used to determine time to temperature and the heating pattern on the post.

The plastic handle is slid on to the picks or mirror. The assembly is placed inside the induction heating coil and

heated. Parts are cooled in position before being removed from the coil.

To heat one end, vertical positioning is optimal (shown). A dual coil design for simultaneous heating of both ends requires horizontal positioning.

Results/Benefits Time and current required for parts:

Mirror: 265 A @ 7.5 sec

Big hook: 205 A @ 7.00 sec

K Curve: 120 A @ 5.00 sec

Curve: 120 A @ 5.00 sec

Reliable bonds are produced when the diameters of the preassembled parts are consistent with little clearance before they are heated.

Material Magnetic steel posts Plastic handle

Temperature indicating paint

Temperature 300°F (149°C)

Frequency 288 kHz

Equipment Power of 6 kW, 100-400 kHz induction heating power supply, equipped with a remote heat station containing a 0.66 μF capacitor.

A folded pancake induction heating coil designed and developed specifically for this application.

Process Initial tests were conducted on parts without any plastic

assembly. Temperature indicating paint is used to determine time to temperature and the heating pattern on the post.

The plastic handle is slid on to the picks or mirror. The assembly is placed inside the induction heating coil and

heated. Parts are cooled in position before being removed from the coil.

To heat one end, vertical positioning is optimal (shown). A dual coil design for simultaneous heating of both ends requires horizontal positioning.

Results/Benefits Time and current required for parts:

Mirror: 265 A @ 7.5 sec

Big hook: 205 A @ 7.00 sec

K Curve: 120 A @ 5.00 sec

Curve: 120 A @ 5.00 sec

Reliable bonds are produced when the diameters of the preassembled parts are consistent with little clearance before they are heated.

Good

Bad

Related Content

induction melting metal sand after air cooled preheating

Remove plastic coating from steel tubes by Induction Heating

Induction heating for Plastic Reflow With Catheter Tubing

induction bonding for glass frit sealing and metal alloy

induction melting steel or rare metal

induction bonding camera lens

induction hardening metal surface

Induction Bonding Solar Panel Shingles

Newest Comment

will you please quote me a price in US dollars.

It would be shipped to Los Angeles, Ca.

I would be using this sealer to seal polypropylene bags of popcorn. I would need it ASAP.

Post Comment