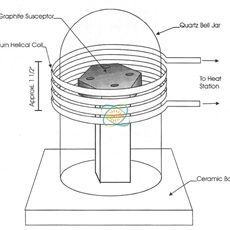

Induction Heating Graphite Susceptor Type:

Induction Heating Graphite Susceptor Type:

Class: Other Induction ApplicationsIntro: Heating Graphite Susceptor Heating Graphite SusceptorObjectiveTo Heat a graphite susceptor to 1100C in an inert atmosphere of Nitrogen and Hydrogen. The susceptor is to be used for metal oxide chemical vapor deposition (MOCVD) crystal growth experimen…

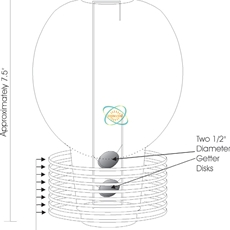

Induction Heating Light Bulbs Type:

Induction Heating Light Bulbs Type:

Class: Other Induction ApplicationsIntro: Objective To heat two 0.5″ getters to a red glow inside a light bulb inorder to fire the getters within 8 seconds. Presently the bulbsare lowered onto an eight station turnstile with an index time of8 seconds.Material Metal Halide Lamp containing two 0.5″

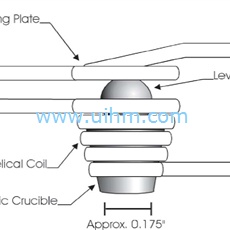

Levitation induction melting system Type:

Levitation induction melting system Type:

Class: Other Induction ApplicationsIntro: Objective Design a modular electromagnetic levitor (MEL) to aid in the study of RF systems used to process metals in the microgravity of space. Nickel and copper are melted and levitated. A reliable system is to be developed to provide repeatable performa

Induction Hardening Teeth Of Gear Type:

Induction Hardening Teeth Of Gear Type:

Class: Induction HardeningIntro: Objective Hardening teeth on a steel motorcycle gear to a hardness of 48 – 55 HRCMaterial Carbon steel gear 6.9” (175mm) diameterTemperature 2000 F ( 1093 C)Frequency 78 kHzEquipment •UM-HF-90 kW induction heating system, equipped with a remote workhead…

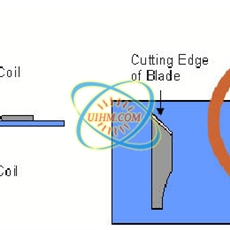

Induction Hardening surgical blades Type:

Induction Hardening surgical blades Type:

Class: Induction HardeningIntro: Objective To quickly heat a steel surgical blade to 2000F (1093C) within 2 seconds so as to harden the blade edge.Material Stainless steel surgical blades, temperature sensing paintTemperature 2000F (1093C)Frequency 339kHzEquipment UM-UHF-6kW induction he

induction Hardening applications Type:

induction Hardening applications Type:

Class: Induction HardeningIntro: UIHM induction surface hardening applications one application: under torsion and bending load of the alternating workpieces requiring surface layer under the Ministry of higher stress than the heart or abrasion on the surface to be made to strengthen the

Steel Induction heat treatment Type:

Steel Induction heat treatment Type:

Class: Induction Thermal TreatmentIntro: Overall heat treatment is heating the whole piece, then the appropriate speed cooling, to change its overall mechanical properties of the metal heat treatment process. Roughly the overall heat treatment of steel annealing, normalizing, quenching and tempe

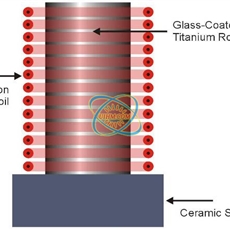

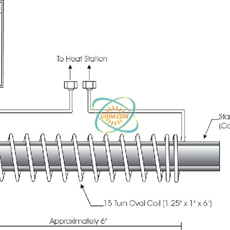

Induction Hot Forming Titanium Rod Type:

Induction Hot Forming Titanium Rod Type:

Class: Induction Thermal TreatmentIntro: Objective To heat a titanium rod to 1700F (926.7C) within 60 seconds for hot forming.Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) lengthTemperature 1700F (926.7C)Frequency 70 kHzEquipment • UM-HF-60kW induction heating system, equipped with…

Induction Stainless Steel Hot Forming Type:

Induction Stainless Steel Hot Forming Type:

Class: Induction Thermal TreatmentIntro: Objective: To heat a stainless steel “J” tape to 3000F from room temperature at a rate of 15 feet per minute. The material is to be heated to aid in forming the “J” shape from flat stock.Material: Stainless Steel “J” Tape measuring 0.562″ wide, 0.02…

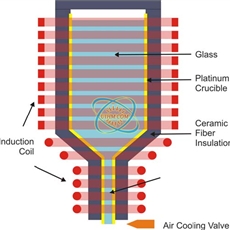

Induction Melting Glass For Fiber Drawing Type:

Induction Melting Glass For Fiber Drawing Type:

Class: Rare Metals MeltingIntro: Objective To heat a metal susceptor vessel to 2200F within 25 minutes for a fiberglass melting applicationMaterial Metal susceptor vesselTemperature 2200FFrequency 300KHZEquipment UM-UHF-60 kW RF power supply, remote heat station and a specially-design

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship