Induction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.

UIHM Induction Melting Furnace provides very efficient & time saving melting of metals for various applications

Features:

- Eco-friendly due to noiseless and flameless operation

- Application Specific

- Auto or manual mode operation

- Improved power factor

- Tropicalised design

- No statutory approvals required

- Lesser risk involved compared to conventional methods

- Compact size

- Uniform metal melting due to induction churning

- Less oxidation loss

- Highest system efficiency

- Highly adaptable for automation

- Easier molten charge handling

- No pre-heating required

- Cost efficient & energy saving

UIHM Induction melting has developed different solutions within a variety of areas such as precious metals, tilting furnace melting, investment casting and lab applications.

With an induction melting furnace the process is considerably cleaner than with a traditional furnace. This means you don't need to purify after the melting, which makes it possible to cut one step in the production process. Lower maintenance costs and machine inventory are some of the benefits.

Induction melting is also safer and more cost-effective. No flame that leads to substantial heat losses or increases the risk of work injuries and fires.

In addition, induction melting is accurate and repeatable—important to secure the quality in your melting processes.

Applications:

- acuum Induction Melting.

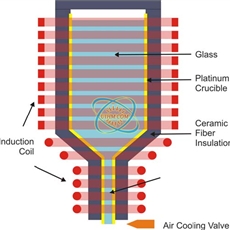

- Platinum Melting.

- Very high Temperature Induction Melting.

- Levitation Melting Systems in microgravity of space.

- High Temperature ceramic melting furnace.

- Crystal Growing.

- Alloy Melting.

- Aluminium Foundry.

- Gold Melting.

- Silver Melting.

- Steel Foundry.

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction melting metal sand after air cooled preheating

induction melting steel

induction melting silver

induction melting copper billets

induction melting steel powder by tilting furnace and MF induction heater

induction melting steel powder

induction melting steel plates

induction melting steel pipes

induction melting silver wires

induction melting silver pieces

induction melting silver by MF tilting furnace

induction melting shells for medicine or pharmacy

induction melting cowry for medicine with graphite crucible

induction melting copper material

induction melting silicon and steel Type:

induction melting silicon and steel Type:

Class: Induction MeltingIntro: induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass Type:

magnesium oxide acidic furnace for induction melting glass Type:

Class: Induction MeltingIntro: magnesium oxide acidic furnace for induction melting glass (1)magnesium oxide acidic furnace for induction melting glass (2)

induction melting with Titanium alloy pot by customized induction coil Type:

induction melting with Titanium alloy pot by customized induction coil Type:

Class: Rare Metals MeltingIntro: induction melting with Titanium alloy pot by customized induction coil (1)induction melting with Titanium alloy pot by customized induction coil (2)

Press←or→to turn page

Recommended

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction melting aluminium

induction melting with vacuum furnace

Medium frequency vacuum melting furnace

medium frequency induction melting solder splash(tin dross)