About UIHM

UIHM was established in 2000, specializing in the production and processing of ultra-high frequency, high frequency, radio frequency, and medium frequency series induction heating equipment and related products.

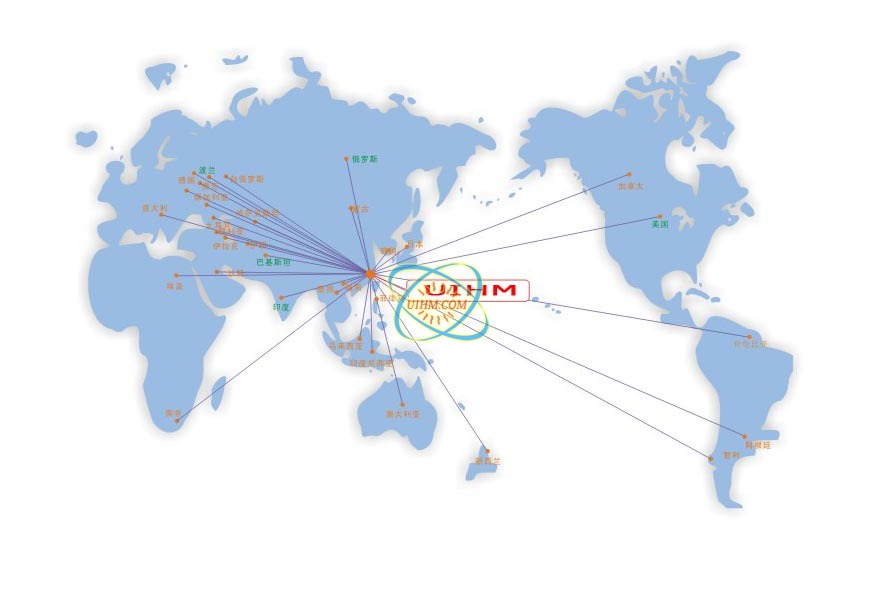

UIHM has a complete and scientific quality management system and strong marketing ability, products in nearly 60 countries and regions throughout the world.

UIHM is top induction heating equipment products and technology services provider in China.

UIHM induction heating machines' quality are trusted by the global professional users.

Under the effort of several years, we have produced series of high quality, various types and advanced capability production.

And we can also exclusively produce these productions on your requirement to meet you need.

We have a wholesome distribution network.

We also build up a lot of offices to provide prompt and quick service to its consumers, to provide after-sale service.

Welcome you to contact us to find more information about our products.

Applications of Induction Heating

Induction furnace

Induction heating allows the targeted heating of an applicable item for applications including surface hardening, melting,brazing and soldering and heating to fit. Iron and its alloysrespond best to induction heating, due to their ferromagneticnature. Eddy currents can, however, be generated in any conductor, and magnetic hysteresis can occur in any magnetic material. Induction heating has been used to heat liquid conductors (such as molten metals) and also gaseous conductors (such as a gas plasma - see Induction plasma technology). Induction heating is often used to heat graphite crucibles (containing other materials) and is used extensively in the semiconductor industry for the heating of silicon and other semiconductors. Utility frequency (50/60 Hz) induction heating is used for many lower cost industrial applications as inverters are not required.

Induction furnace

An induction furnace uses induction to heat metal to its melting point. Once molten, the high-frequency magnetic field can also be used to stir the hot metal, which is useful in ensuring that alloying additions are fully mixed into the melt. Most induction furnaces consist of a tube of water-cooled copper rings surrounding a container of refractory material. Induction furnaces are used in most modern foundries as a cleaner method of melting metals than a reverberatory furnace or a cupola. Sizes range from a kilogram of capacity to a hundred tonnes capacity. Induction furnaces often emit a high-pitched whine or hum when they are running, depending on their operating frequency. Metals melted include iron and steel, copper, aluminium, and precious metals. Because it is a clean and non-contact process it can be used in a vacuum or inert atmosphere. Vacuum furnaces make use of induction heating for the production of specialty steels and other alloys that would oxidize if heated in the presence of air.

Induction welding A similar, smaller-scale process is used for induction welding. Plastics may also be welded by induction, if they are either doped with ferromagnetic ceramics (where magnetic hysteresis of the particles provides the heat required) or by metallic particles.

A similar, smaller-scale process is used for induction welding. Plastics may also be welded by induction, if they are either doped with ferromagnetic ceramics (where magnetic hysteresis of the particles provides the heat required) or by metallic particles.

Seams of tubes can be welded this way. Currents induced in a tube run along the open seam and heat the edges resulting in a temperature high enough for welding. At this point the seam edges are forced together and the seam is welded. The RF current can also be conveyed to the tube by brushes, but the result is still the same — the current flows along the open seam, heating it.

Induction cooking

In induction cooking, an induction coil in the cook-top heats the iron base of cookware. Copper-bottomed pans, aluminium pans and other non-ferrous pans are generally unsuitable. The heat induced in the base is transferred to the food via (metal surface) conduction. Benefits of induction cookers include efficiency, safety (the induction cook-top is not heated itself) and speed. Both permanently installed and portable induction cookers are available.

Induction brazing

Induction brazing is often used in higher production runs. It produces uniform results and is very repeatable.

Induction sealing

Induction heating is used in cap sealing of containers in the food and pharmaceutical industries. A layer of aluminum foil is placed over the bottle or jar opening and heating by induction to fuse it to the container. This provides a tamper-resistant seal, since altering the contents requires breaking the foil.

Heating to fit

Induction heating is often used to heat an item causing it to expand prior to fitting or assembly. Bearings are routinely heated in this way using utility frequency (50/60 Hz) and a laminated steel transformer type core passing through the centre of the bearing.

Heat treatment

Induction heating is often used in the heat treatment of metal items. The most common applications areinduction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an area of a steel part.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

Limits to the flexibility of the process arise from the need to produce dedicated inductors for many applications. This is quite expensive and requires the marshalling of high current densities in small copper inductors, which can require specialized engineering and 'copper-fitting'.

Plastic processing

Induction heating is used in plastic injection molding machines. Induction heating improves energy efficiency for injection and extrusion processes. Heat is directly generated in the barrel of the machine, reducing warm-up time and energy consumption. The induction coil can be placed outside thermal insulation, so it operates at low temperature and has a long life. The frequency used ranges from 30 kHz down to 5 kHz, decreasing for thicker barrels. The reduction in cost of inverter equipment has made induction heating increasingly popular.[citation needed] Induction heating can also be applied to molds, offering more even mold temperature and improved product quality.

Details

The basic setup is an AC power supply that provides electricity with low voltage but very high current and highfrequency. The workpiece to heat is placed inside an air coil driven by the power supply, usually in combination with a resonant tank capacitor to increase the reactive power. The alternating magnetic field induces eddy currents in the workpiece.

Magnetic materials improve the induction heat process because of hysteresis. Materials with high permeability(100–500) are easier to heat with induction heating. Hysteresis heating occurs below the Curie temperaturewhere materials lose their magnetic properties. High permeability below the Curie temperature in the workpiece is useful. Temperature difference, mass, and specific heat influence the workpiece heating.

The energy transfer of induction heating is affected by the distance between the coil and the workpiece. Energy losses occur through heat conduction from workpiece to fixture, natural convection, and thermal radiation.

The induction coil is usually made of copper tubing and fluid cooled. Diameter, shape, and number of turns influence the efficiency and field pattern.

Core type furnace

The furnace consists of a circular hearth which contains the charge to be melted in the form of angular ring. The metal ring is large in diameter and is magnetically interlinked with an electrical winding energized by an AC source.