Induction Heating Light Bulbs

Views Send Enquiry

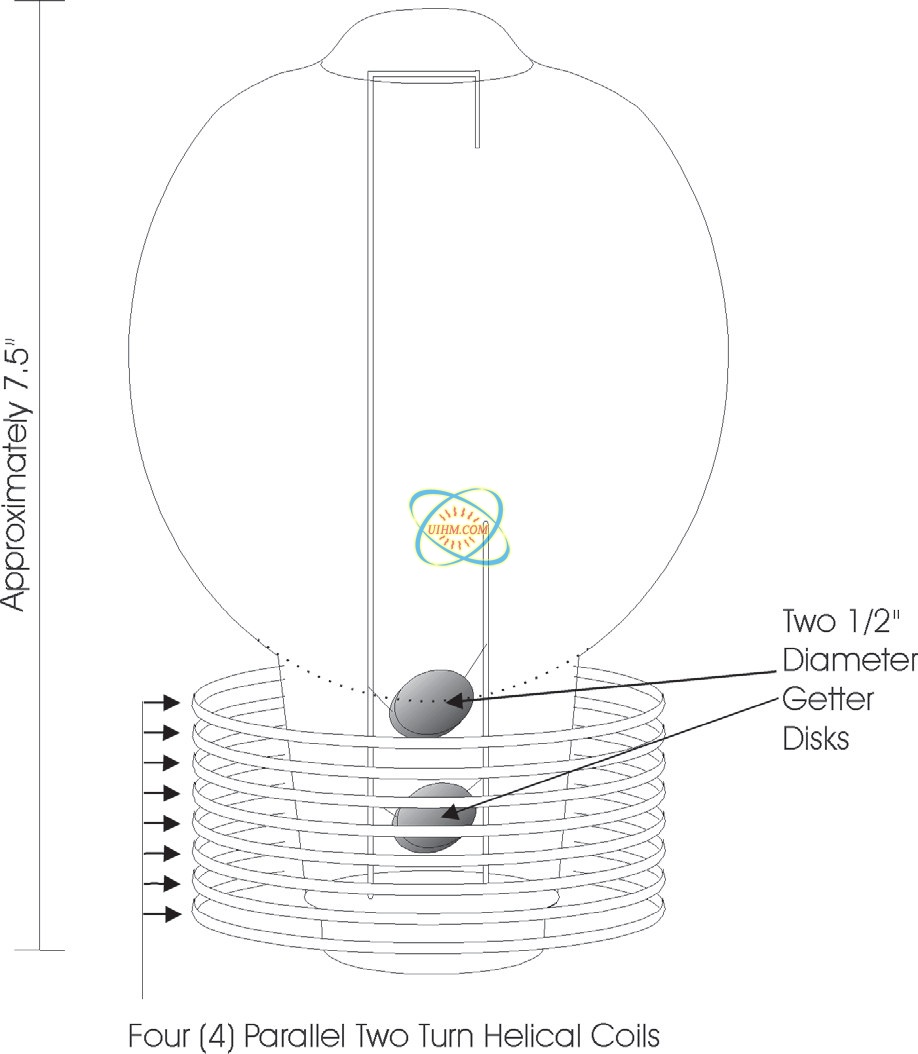

Objective To heat two 0.5″ getters to a red glow inside a light bulb in

order to fire the getters within 8 seconds. Presently the bulbs

are lowered onto an eight station turnstile with an index time of

8 seconds.

Material Metal Halide Lamp containing two 0.5″ diameter getters of

unknown composition.

Temperature 1300ºF to 1500ºF

Frequency 350 kHz

Equipment Power of 6 kW solid state induction power supply including one remote heat station containing one (1) capacitor totaling 0.66 μF, and a unique coil comprised of four (4) parallel two (2) turn coils.

Process By using the UIHM 5 kW solid state induction power supply the following results were achieved:

Results • Both getters were fired within 2.5 seconds through the use of a unique helical coil comprising of four (4) parallel two (2) turn coils and the 4-20 mA fast ramp input.

• The 2.5 second firing cycle allows for the coil to be move around the part and away within the indexing time

of the turnstile table.

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment