Induction Brazing carbide teeth to steel pipe Type:

Induction Brazing carbide teeth to steel pipe Type:

Class: HF Induction BrazingIntro: Objective Brazing carbide teeth to a steel jaw in less than 5 minutesMaterial Steel pipe jaw, 0.5” (12.7mm) dia, 1.25” (31.75mm) long, 0.25” (6.35mm) thick carbide teeth, black flux and silver copper braze shimsTemperature 1292F (700C)Frequency 257kHzEq…

Induction Brazing Bourdon Tube Type:

Induction Brazing Bourdon Tube Type:

Class: HF Induction BrazingIntro: Objective To braze a thin copper oval tube to a brass fitting at 1400 F and to cap the other end of the copper tube with a brass plate.Material Brass fitting – 0.875 in2 and 2.5 in long (22mm2 x 64mm) Copper tube 0.01 in (0.254mm) wall Brass plate 0.10 i

Induction Brazing Brass Fittings Type:

Induction Brazing Brass Fittings Type:

Class: HF Induction Brass SolderIntro: Objective To heat brass tubing assemblies to 750C for a brazing application. The tubing diameter varies from 3 to 8 inches (76.2 to 203.2 mm)Material Brass tubingBrass flangeBraze ringsBraze fluxTemperature 1382F (750C)Frequency 100 kHzEquipment UM-HF-45

Induction Brazing carbide shaft to steel tube Type:

Induction Brazing carbide shaft to steel tube Type:

Class: HF Induction BrazingIntro: Objective Braze a carbide shaft to a steel tubeMaterial Carbide shaft 1/8” to 1” diameter (varying sizes) Steel tube 3/8” to 1 ” OD Silver solder brazeTemperature indicating paintTemperature 1400 F for 60 secondsFrequency 220 kHzEquipment UM-UHF-6kW, 1…

Induction Brazing Diamond Drill Type:

Induction Brazing Diamond Drill Type:

Class: HF Induction BrazingIntro: Objective To braze diamond inserts to a steel drilling ringMaterial • steel ring and diamond inserts• Braze shim preform• FluxTemperature 1300 – 1350 (700 – 730) F (C)Frequency 68 kHzEquipment UM-HF-35 kW, induction heating system, equipped with a rem…

Induction Brazing carbide tool Type:

Induction Brazing carbide tool Type:

Class: HF Induction BrazingIntro: Objective Braze carbide rotary file assemblies with uniform concentricity in an aerospace applicationMaterial • Carbide blank• High speed steel shank• Temperature indicating paint• Braze shim and black fluxTemperature 1400F (760C)Frequency 252 kHzEquip…

Induction Brazing Cutting Tool Type:

Induction Brazing Cutting Tool Type:

Class: HF Induction BrazingIntro: Objective To braze cone and shaft for a cutting toolMaterial Customer supplied partsTemperature indicating paintBraze preformsTemperature 1300 – 1400 F (704 – 760 C)Frequency 235 kHzEquipment UM-UHF-6 kW, 150-400 kHz induction heating system, including r…

Induction Brazing Copper Fittings Type:

Induction Brazing Copper Fittings Type:

Class: HF Induction Brass SolderIntro: Objective Copper ‘tees’ and ‘ells’ are to be brazed to the aluminum body of a refrigeration valveMaterial customer valvecopper fittingsbrazeTemperature 2550 F (1400C)Frequency 285 kHz Equipment UM-UHF-15KW induction heating system including a workhea…

Induction Brazing Carbide Tips Type:

Induction Brazing Carbide Tips Type:

Class: HF Induction BrazingIntro: Objective Attaching carbide cutters to a steel meat cutter impellerMaterial carbide blocks; steel shank fittingTemperature 1400 F (760 C)Frequency 219 kHzEquipment UM-UHF-30kW induction heating systems including:Induction heating coilWorkhead: two-cap 1.0

Induction Brazing Brass Fitting to Copper Air Lines Type:

Induction Brazing Brass Fitting to Copper Air Lines Type:

Class: HF Induction Brass SolderIntro: Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment UM-UHF-6KW induction heating system, including a

Recommended

induction brazing SS steel by handheld induction coil

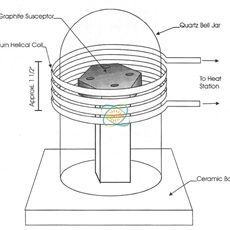

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship