Induction Annealing Motor Shaft Type:

Induction Annealing Motor Shaft Type:

Class: HF Induction AnnealingIntro: Objective Annealing the end of a steel hydraulic motor shaft prior to machiningMaterial .75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the endTemperature 1350 F (732 C)Frequency 359 kHzEquipment • UM-06A-UHF induction heating system,…

Induction Annealing aluminum tubing Type:

Induction Annealing aluminum tubing Type:

Class: HF Induction AnnealingIntro: Objective Annealing aluminum fuel tank fill neck to 650 F (343 C)Material Aluminum fill neck 2.5” (63.5mm) diameter, 14” (35.5cm) longTemperature 650 F (343 C)Frequency 85 kHzEquipment • 40kW induction heating system, equipped with a remote workhead con…

Induction Annealing brass wire Type:

Induction Annealing brass wire Type:

Class: HF Induction AnnealingIntro: Objective Continuously anneal a brass wire used in electric motors at a rate of 16.4 yds (15m) per minute to eliminate work hardening caused during the drawing process.Material Square copper wire 0.06” (1.7mm) dia., temperature indicating paintTemperature

Induction Annealing aluminum lip Type:

Induction Annealing aluminum lip Type:

Class: HF Induction AnnealingIntro: Objective Annealing a 1” lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming.Material Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thickTemperature 800 F (427 C)Frequency 303 kHzEquipment •…

Induction Annealing Steel Wire Type:

Induction Annealing Steel Wire Type:

Class: HF Induction AnnealingIntro: Objective To heat 3” (76.2mm) from the end of the wire on a woven wire cloth 60” (1.52m) long. This prepares the wire mesh for bending in a press brake.Material Woven wire cloth (steel) made of 1/2” (12.7) diameter wire, 60” (1.52m) long. Wires are 1.5…

Induction Annealing copper tubing Type:

Induction Annealing copper tubing Type:

Class: HF Induction AnnealingIntro: Objective To heat both ends of a copper tube to anneal as soft as possible 1.5” (38.1mm) from end and retain full hardness next to annealMaterial 1.625” (41.275mm) dia x 24” (609.6mm) long copper tubeTemperature 1500 F (815.5 C)Frequency 70 kHzEquipment…

Induction Annealing Brass crimping Type:

Induction Annealing Brass crimping Type:

Class: HF Induction AnnealingIntro: Objective To anneal a small area of an electrical contact for crimpingMaterial Brass female spade electrical contact with single transverse loop at end 0.5h(12.7mm) long, 0.25h(6.3mm) wide and 0.03h (0.8mm) thick, 1000oF (538oC)heat paintTemperature …

Induction Annealing steel shaft Type:

Induction Annealing steel shaft Type:

Class: HF Induction AnnealingIntro: Objective Heating a steel rod to 1200F (649C) for an annealing, stress relief applicationMaterial 1.062” (26.97mm) dia type T-410 stainless steel bar 6’ (1.82m) long & 1.25” (31.75mm) dia T-416 stainless steel bar 6’ (1.82m) longTemperature 1200F (…

Induction Annealing locknuts Type:

Induction Annealing locknuts Type:

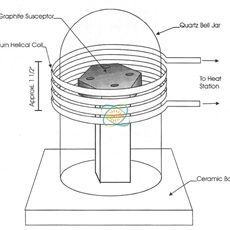

Class: HF Induction AnnealingIntro: Objective To heat locknuts to 2150F (1176C) for annealingMaterial Waspaloy locknutTemperature 2150F (1176C)Frequency 382 kHzEquipment • UM-10AB-UHF induction heating system, equipped with a remote workhead containing one 0.66μF capacitor.• An induction …

Induction Annealing metal stamp sets Type:

Induction Annealing metal stamp sets Type:

Class: HF Induction AnnealingIntro: Objective Heat the opposite end of a metal stamp so that it mushrooms instead of cracks/splits when struck by a hammer.Material S-7 steel of varying rectangular cross sectional sizesTemperature 1400-1800 F (760-982) CFrequency 204-165 kHzEquipment 25 kW,

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship