-

Keywords"tin",total

1228 records

-

induction shrink fitting carbide ring

Shrink fitting carbide ring Objective Shrink fitting a carbide ring into a steel valve seatMaterial Steel valve seat 6” (152.4mm) OD with 3” (76.2mm) ID hole & .75” (19mm) thick, carbide ringTemperature 500 F ( 260 C)Frequency 55 kHzEquipment • Pow…

-

induction shrink fitting impeller blades to shaft

Shrink fitting impeller blades to shaft Objective Heat aluminum impeller blades to 200 F (93 C) and shrink fit onto a shaft.Material Aluminum impeller blades with a .28” (7.109mm) bore, aluminum shaftTemperature 200 F (93 C)Frequency 255 kHzEquipment • P…

-

induction shrink fitting pulley to insert bearing

Shrink fitting pulley to insert bearing Objective Heat aluminum pulley for insertion of an inner bearing for the automotive industryMaterial Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (…

-

induction shrink fitting wrist pin into connecting rod

Shrink fitting wrist pin into connecting rod Objective Assemble connecting rods with a more accurate control of the heatMaterial Rod has an OD of .9125” (23.18mm), knuckle has an ID of .9125” (23.18mm) with an interference of .0001” (.0025mm). Knuckle a…

-

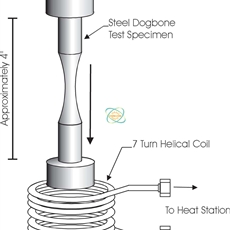

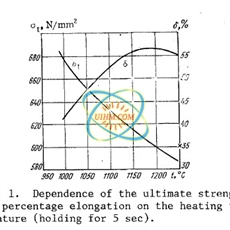

induction heating steel dogbone specimen

Heating Steel Dogbone Specimen Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the gage ar…

-

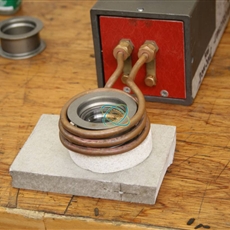

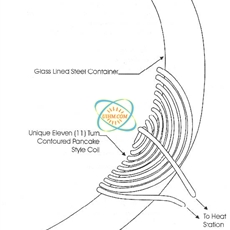

induction heating repair lined steel tank

Heating Repair Lined Steel Tank Objective: To heat selected areas of a glass lined steel tank to 16000F in order to perform repairs of cracks and chips. The glass is used as a frit which must be reflowed and filled into the damaged areas. Temperature contr…

-

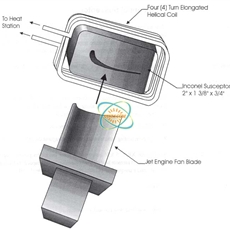

induction heating inconnel susceptor

Heating Inconnel Susceptor Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be achi…

-

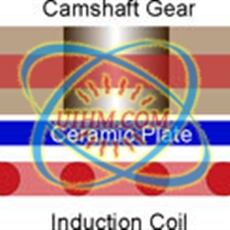

induction shrink fitting cam shaft gears

Shrink Fitting Cam Shaft Gears Objective To heat aluminum and steel camshaft gears to over 500F within 4 minutes for a shrink fitting application.Material 6” diameter, 2” thick steel and aluminum camshaft gears, “K” type thermocouple, digital thermomet…

-

induction levitation melting steel balls

Levitation melting steel balls Objective Levitation of steel balls during the melting processMaterial 1010 low carbon steel balls ” (6.35mm) diameterTemperature 2800 F (1538 C)Frequency 195 kHzEquipment • Power of 30 kW induction heating system, equipped…

-

heat treatment with induction heating of within pipes

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat-trea…