-

Keywords"tin",total

1228 records

-

annealing an effective heating process

There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire indu…

-

film capacitor module in the application of induction heating system

Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began …

-

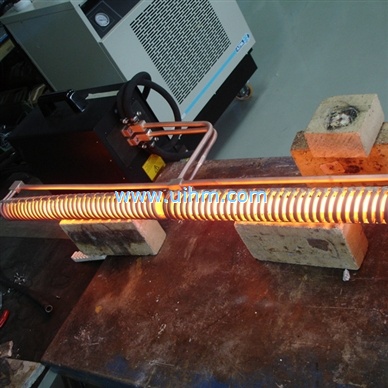

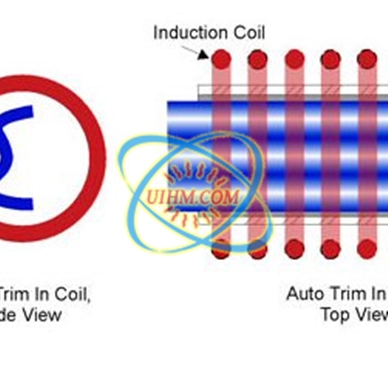

induction heating aluminum auto trim

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive. Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube Temperature :50…

-

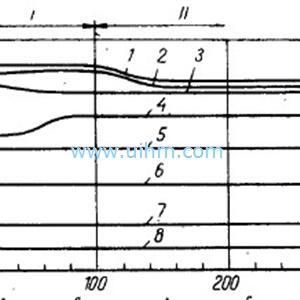

effect of surface hardening by induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…

-

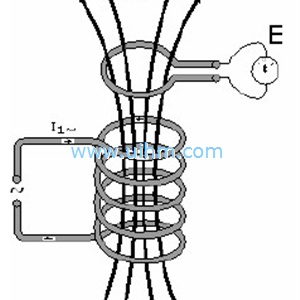

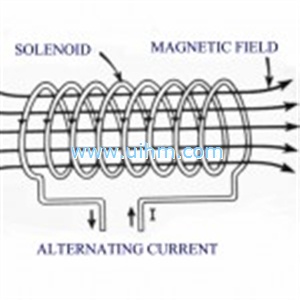

simpley heating by induction

Electromagnetic induction, simply induction, is a heating technique for electrical conductive materials (metals). Induction heating is frequently applied in several thermal processes such as the melting and the heating of metals. Heating by Induction has …

-

induction heating billets

The induction heating of round bars and round-corner-square (RCS) billets are often treated as equivalent applications, even though they are not. This article reconciles recent theoretical and practical achievements in providing required heat uniformity wh…

-

heat treating forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity. The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac …

-

induction heating technology in aerospace

The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a …

-

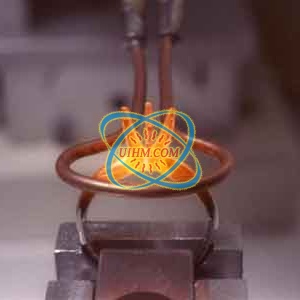

why use induction heating

Induction Heating is a GREEN process as it does not emit fumes or CO2 into the environment, emissions are controlled by the electricity generating company at one site and are easy to monitor. The result of only a small proportion of the material bei…

-

advantages of induction heating

Why choose induction heating over convection, radiant, open flame or another heating method? Heres a short summary of the major advantages that modern solid state induction heating offers for lean manufacturing:Optimized Consistency Induction heating elim…