-

Keywords"tin",total

1228 records

-

induction heating principle and its application in the construction machinery

Induction Heating is the process of heating condutive material or magnetic condutive material (usually a metal, but also including graphite, molten salts, oxides, carbides, plasma etc.) by electromagnetic induction method, the changing magnetic fields gene…

-

special graphatie melting furnace

special graphatie melting furnace

-

advantages and disadvantages of induction heating technology

Many people want to know what is advantage and disadvantage of induction heating, induction hardening,induction brazing,induction forging,induction melting or induction quenching.High frequency induction machines and induction heating technology is current…

-

melting furnace reach 1650 degree c

melting furnace reach 1650 degree C

-

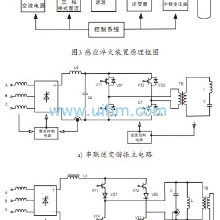

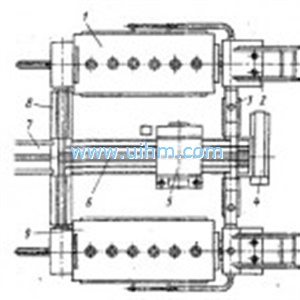

high,medium frequency induction heating quenching furnace engineering design method

0 IntroductionHigh, medium frequency induction heating power supply unit is used for the heat treatment of machine metal parts, widely used in the automobile and other machinery manufacturing industry. The practice shows that the induction heat treatment i…

-

heat-treating-forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity.The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac 3.…

-

the applications of induction heating system

More Welders Resort to Induction Heating For Preheating, Stress-Relieving Traditional Induction Heating Applications – Soldering – Brazing – Surface hardening – Tempering- Bonding – Curing – Encapsulating- Melting- Forging- Super heating- Crystal gro…

-

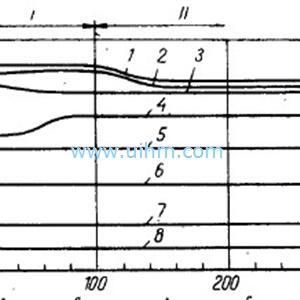

effect of surface hardening by high frequency induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…