-

Keywords"SS",total

284 records

-

induction heat treating proceSS

Heat treating process Heat treating is an essential phenomenon that is very much needed to manipulate the physical, as well as sometimes the chemical properties of a metal. Though it finds its application in the metallurgical process, heat treating is also…

-

induction heat treatment proceSS

Heat Treatment process HEAT TREATMENTWe use heat treatments to change properties of metal, or as a method of controlling formation of structures, or expansion/contractional^forces during welding. In heat treating metals and alloys there are many elements f…

-

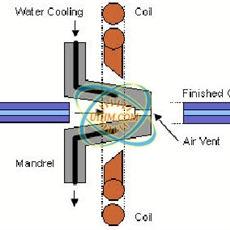

induction heating braSS mandrel die

Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller. Material materials, supplies involved in the application Temperature 400F (204C) Frequency 325kHz Equipment…

-

induction soldering braSS

Soldering brass Objective To solder a brass end cap to a series of copper tubes Material Preassembled heat exchanger with copper tubes and 2 brass end caps 2.36” (60mm) OD, 0.08” to 0.12” (2 to 3mm) thick at both ends, liquid solder Temperature 30…

-

induction soldering braSS and copper

Soldering brass and copper Objective To heat brass and copper for soldering application on medical equipmentMaterial Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder ringsTemperature 3…

-

induction soldering stainleSS steel

Soldering stainless steel Objective Heat Stainless steel connector for soldering application in automotive wire harness manufacturingMaterial Stainless steel connector 1.57” (40mm) long, 0.6” (15mm) OD & 0.4” (10mm) thick. Lead free solderTemperatur…

-

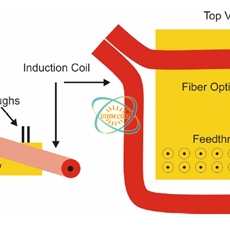

induction soldering glaSS feedthroughs

Soldering Glass Feedthroughs Objective Heat a kovar fiber optic housing with glass feed-throughs to 400F (204.4C) within 20 seconds for a soldering application, to form a hermetic seal Material Kovar housing with 18 glass feed-throughs, solder preformsand …

-

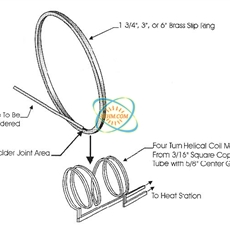

induction soldering braSS rings

Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick feed…

-

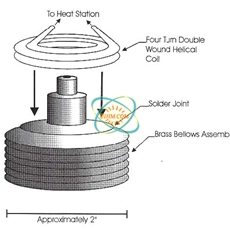

induction soldering braSS bellows aSSembly

Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality solder j…

-

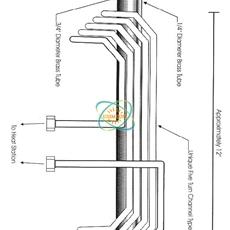

induction soldering braSS tubes

Soldering brass tubes Objective: Soldering two brass tubes measuring 3/4 and 1/4 together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to be m…