Induction Heat treating process

Views Send Enquiry

Heat treating is an essential phenomenon that is very much needed to manipulate the physical, as well as sometimes the chemical properties of a metal. Though it finds its application in the metallurgical process, heat treating is also held to be important in the making of some other materials like that of glass. Normally, the process involves heating and chilling of the related material at extreme temperatures to get the desired result, such as the hardening and softening of the same material. Any material that goes through heat treatment involves certain process like that of annealing, case hardening, precipitation hardening, quenching, and tempering. However, it should be noted that heat treating necessarily relates when it is done intentionally. Or else, there are certain times, like hot forming or welding, when the process of heat treatment takes place incidentally.Metals consist of micro structures that are popularly known as grains or crystallites. The size and composition of these crystallites play a pivotal role in determining the overall behaviour of the related metals. The process of heat treatment is designed to manipulate these governing properties of the metal through controlling the rate of diffusion or cooling. There are two broad mechanisms that play an instrumental role in making this process going. These are: 1. Martensite transformation: This allows the crystallites to deform intrinsically, and2. Diffusion mechanism: This allows a change in the homogeneity of the metal alloys. The crystallites of a metal are consisted of atom that is formed in a certain arrangement which is better known as lattice. At different temperatures, these arrangements are tend to change due to the inception of the process of heat treating. Unlike the alloys that have an iron base, most of the alloys that are heat treated do not witness a ferrous transformation.Below we will further discuss about the some of the procedures that are involved into the formulation of heat treating of a material:1. Annealing: This involves the process of heating any specific metal under a certain prescribed limit and then instantly cooling it off so that the resultant material will consist a more refined set of micro structural arrangement. Annealing is usually performed to soften any metal to improve its machinability, to enhance cold working, or to improve the properties like that of electrical conductivity of the metal.2. Normalising: This is usually practised in heating any ferrous material well above the critical temperature limit and then cooling off the same in the open air. This technique is undergone to offer a uniformity of the grain size and composition of an alloy.3. Stress Relieving: This process is performed by heating any metal well below the lower critical temperature and then cooling it off in a uniform manner.4. Aging: References of this very process can be made to the 2000 series, the 6000 series, and the 7000 series of aluminium alloy. Apart from these, there are also some super-alloys and variations of stainless steels that seek an example to the process of aging.

We are blessed with a number of improved and useful devices and systems that have changed our life. From health, education, communication to entertainment, science and technology has touched every area. Health industry is witnessing a lot of improvements as a result of the introduction of scientific interference. Now, it has become easy to treat some of the problems that doctors could not handle in the past. The process of induction hardening is almost similar to any other heat treating operations. It is mainly performed to harden parts. The procedure is dependent on various factors to be successful, adjusting the temperature of the material, the general ability and chemistry of the material to harden, proper cooling of the material so that the transformation of the martensite can occur. When one or more than one of these critical characteristics are not present, the material may remain soft entirely or it may end with soft spots. So, it is very essential to check whether all these factors are present or not. Most of these factors help in quenching and heating of the parts. There are different types of heat treatment processes, including Annealing, Ageing, Hardening, Induction Annealing, Carbonitriding, Case Hardening, Carburising, Induction Hardening, Stress Relieving, Shot Blasting, Shot Blasting, Normalising and Tempering to materials like Cast Irons, Alloy Steels, Stainless Steels, Die Steels, Tool Steels, Carbon steels etc. Ageing is the process that causes structural change. It may occur in certain alloys and certain metals at atmospheric temperature or at higher temperatures (also called as artificial ageing). As a result of ageing, the hardness value and maximum stress are increased. You should make it sure that there is some reduction in ductility. Artificial ageing is a process in which the ageing is created by heating at high temperature. It results in precipitation hardening. It is one of the best heat treatment processes. It is quite essential to adjust the temperature of the material so that the austenitic phase can occur. In certain cases, based on the material, it may be essential to hold the temperature for a certain amount of time. It is done to allow the material to avoid undesirable by-products and also allow to fully transforming. There are many other types of heat treating operations that are used. Annealing, Carbonitriding are two of the popular heat treating processes. Annealing is a process in which steel is heated and then the temperature is adjusted properly. Then the cooling is done at a suitable rate, with machinability, with the object of improving softness, of obtaining a desired structure and of removing stresses and cold working properties. Generally the steel is heated to a certain temperature at which carbide is partly or fully taken into solution.

Heat treating alters the behavioural properties of the metals. It is done by applying heat at an extreme temperature to the metal and then cooling it down at a very low temperature. The different forms of heat treat method include annealing, hardening, precipitation, case hardening, selective hardening, ageing and stress relieving. The method used for changing the chemical, physical and mechanical properties of a metal by the application of controlled heating and cooling is popular as heat treatment. This method is basically used for improving or restoring the manufacturability of a product. Heat treat processes are commonly applied in manufacturing, metallurgy, welding and hot forming. Heat treating is applied to raw materials or on the finished products. The method involves heating the materials to extreme temperatures for increasing the internal stress. After heating at extremely high temperature, it is then subsequently cooled down at a very low temperature. This process is known as quenching, which strengthens the internal lattice structure. The process even brings finery in grains, which have an increased tensile power. Some of the most common forms of heat treatment methods include annealing, hardening, precipitation, case hardening, selective hardening, ageing and stress relieving. Heat treating is usually carried out for softening, hardening and materially modifying a product. Softening reduces the material’s hardness while improving the resistance and ductility. It offers toughness and even improves the grain size. This process is popular as annealing. It is typically carried out for restoring the ductility and relaxing the metal stresses in the material. Hardening is carried out usually on steel for increasing its potency and wear and tear properties. Sufficient alloy and carbon content is needed for carrying out the hardening method. When it is present in sufficient quantity, the steel gets hardened directly. If there is lack of carbon content, the method of carbon enrichment may be used for increasing the car carbon ration in the carbon steel components. Ageing is a method that causes structural change. This change occurs slowly in few metals and alloys at an atmospheric temperature or rapidly at a higher temperature. Maximum stress, hardness values and proof stress are increased with reduction in ductility as a result of this heat treating process. Where ageing is produced by heating at an elevated temperature, the effect is referred as precipitation hardening. Precipitation hardening is used in metals that are categorized as metals that fit in the precipitation category. Selective hardening basically uses the method of heat treat on an object, which is popular as differential hardening. Case hardening is also a popular method of heat treatment. It refers to the diffusion of surface on monolithic metals. Stress relieving is the popular method of reducing residual stress in a metal by metal. This is done by heating the metal to a suitable temperature and then holding it for some time so that the internal stress is released by creep. After getting soaked, the metal is cooled down gradually preventing the reintroduction of stress. This heat treatment process is applied to relieve stresses that are induced by quenching, casting, normalising, cold-working, welding or machining.

heat treating process

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

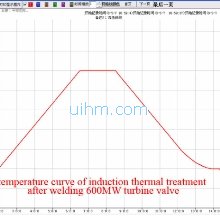

temperature curve of induction thermal treatment after welding 600MW turbine valve

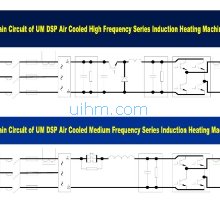

Main Circuit of UM DSP air cooled induction heaters

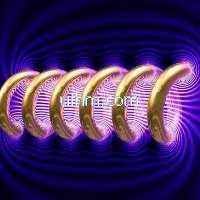

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment