-

Keywords"SS",total

284 records

-

induction brazing two positions on a stainleSS steel manifold

Objective Simultaneously braze two positions on a stainless steel manifold Material Stainless steel manifold 4” (101.6mm) long, 1” (25.4mm) in diameter and nico braze Temperature 1800 F (982 C) Frequency 198 kHz Equipment • Power of 20kW induction h…

-

induction brazing braSS trap block

Objective Block is heated to 1400F to braze trap tube to assemblyMaterial brass block and pre-formed tubesbraze pre-formsTemperature 1400 F (760C)Frequency 357 kHzEquipment Power of 20kW induction heating system including• Coil: custom-designed 2-turn spl…

-

induction brazing stainleSS steel

Objective 1st Application: Braze hub assembly to needle holder 2nd Application: Braze Large tube to ring joint Material 1st Application: Steel hub assembly and needle 0.1” dia (2.5mm) 2nd Application: Steel tube 1” OD (25.4 mm) and ring Temperature 1…

-

induction brazing braSS fittings

Objective To heat brass tubing assemblies to 750C for a brazing application. The tubing diameter varies from 3 to 8 inches (76.2 to 203.2 mm) Material Brass tubing Brass flange Braze rings Braze flux Temperature 1382F (750C) Frequency …

-

induction brazing braSS fitting to copper air lines

Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment Power of 6KW induction heating system, including …

-

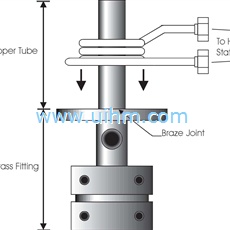

induction braze copper tube to braSS fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300F…

-

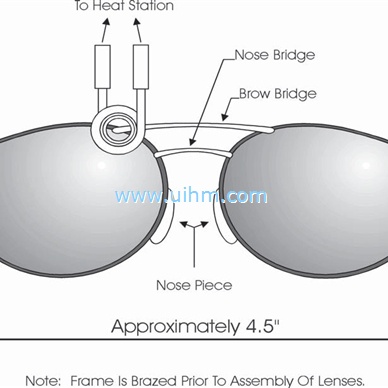

induction brazing eyeglaSS frame aSSembly

Objective Produce repeatable braze joints for the assembly of eyeglass frames. Induction heating is to be used to achieve quality braze joints on the nose bridge, brow bridge and nose piece. Brazing is to be done at 1300F with approximately 3-5 seconds al…

-

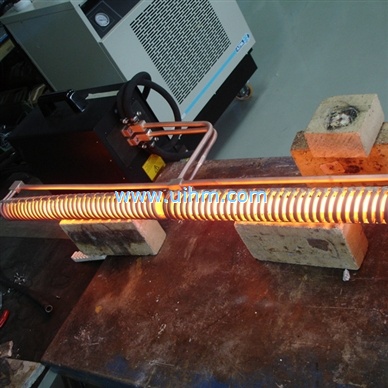

induction annealing braSS wire

Objective Continuously anneal a brass wire used in electric motors at a rate of 16.4 yds (15m) per minute to eliminate work hardening caused during the drawing process. Material Square copper wire 0.06” (1.7mm) dia., temperature indicating paint Tempera…

-

induction annealing braSS crimping

Objective To anneal a small area of an electrical contact for crimpingMaterial Brass female spade electrical contact with single transverse loop at end 0.5h(12.7mm) long, 0.25h(6.3mm) wide and 0.03h (0.8mm) thick, 1000oF (538oC)heat paintTemperature …

-

annealing an effective heating proceSS

There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire indu…