Induction Soldering Glass Feedthroughs

Views Send Enquiry

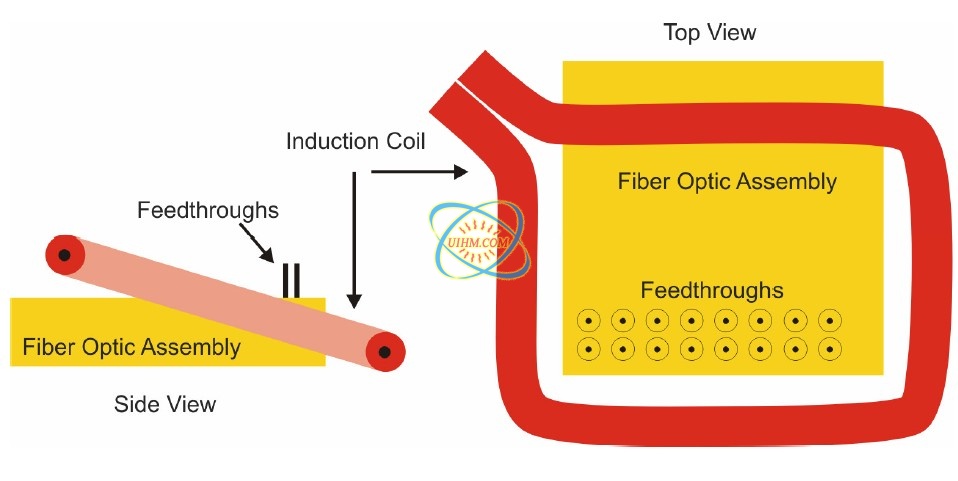

Objective Heat a kovar fiber optic housing with glass feed-throughs to 400°F (204.4°C) within 20 seconds for a soldering application, to form a hermetic seal Material Kovar housing with 18 glass feed-throughs, solder preforms

and flux

Temperature 400 ºF(204.4°C)

Frequency 300 kHz

Equipment • Power of 6 kW RF induction heating system equipped with a remote workhead

• An induction heating coil designed and developed specifically for this application

Process A specially designed single-turn, pancake coil is used to provide uniform heating to the kovar housing. The coil position is adjusted to heat only the front portion of the assembly. The feedthroughs and solder preforms are assembled with flux. Power is applied for 20 seconds, causing the solder to flow cleanly around the feed-throughs.

Results/Benefits Induction heating provides:

• All 18 feedthroughs can be soldered at the same time

• Faster production time & more economical

• Controllable, repeatable results

Soldering Glass Feedthroughs

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Newest Comment

No Comment

Post Comment