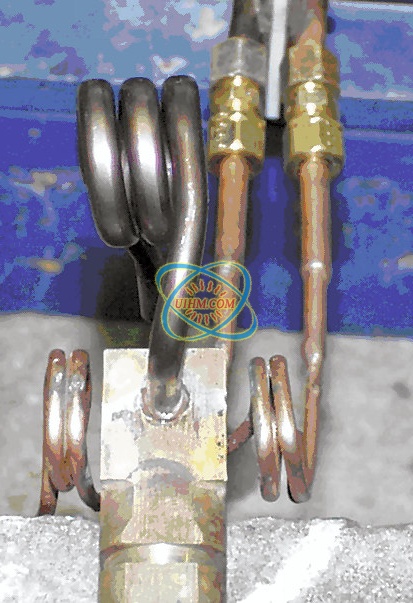

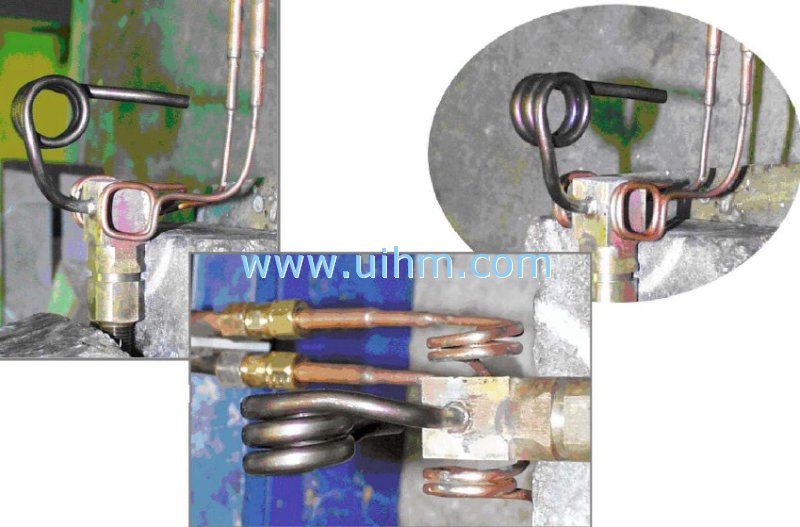

Induction Brazing Brass Trap Block

Views Send Enquiry

Objective Block is heated to 1400°F to braze trap tube to assembly

Material brass block and pre-formed tubes

braze pre-forms

Temperature 1400 ºF (760°C)

Frequency 357 kHz

Equipment Power of 20kW induction heating system including

• Coil: custom-designed 2-turn split-helical

• Workhead: contains two 1.0μF capacitors (0.5 μF total)

Process The brass parts, braze pre-form and flux are assembled and located within the custom-designed coil. Induction heating of the joint is accomplished in 45 seconds.

Results/Benefits Economy: induction heats only the material within the coil; no energy is wasted heating the surrounding materials and air; no flame or gasses required for heating

Control: process lends itself to the use of braze pre-forms;

process easily adapted to automation

Efficiency: energy is expended only during the joint formation.

Induction Brazing Brass Trap Block

Related Content

induction brazing SS steel by handheld induction coil

induction brazing shoe mold

induction brazing drill bit of transformer

induction brazing stator

induction brazing top of condenser pipes by pancake induction coil

induction brazing SS steel parts with auto feed system by UHF induction heater

induction brazing oil tube

induction brazing N type cable connector

Hot

UHF handheld induction heater for brazing copper

UHF handheld induction heater for brazing brass

handheld induction coil for soldering brass

handheld induction coil for brazing brass

induction brass soldering for refrigerator pipes

induction brass soldering with D80mm red copper with 60% silver solder paste

induction brass soldering pipes for chiller

induction brass soldering for multi pipes

Newest Comment

No Comment

Post Comment