-

Keywords"induction",total

2890 records

-

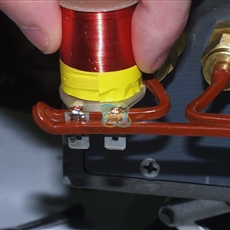

induction soldering wires onto connector

Soldering wires onto connector Objective Heat connector assemblies for solderingMaterial Device assemblyTin plated brass terminals Solder pasteTemperature 500F (260C) 5-7 secondsFrequency 360 kHzEquipment Power of 6 kW induction heating system equipped wit…

-

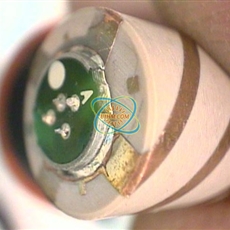

induction soldering satellite antennas

Soldering satellite antennas Objective Soldering steel onto GPS body for phone antennaMaterial Thin copper foil 0.3mm (0.01 in) thick Ceramic body 12mm (0.47 in.) long x 7mm (0.28 in.) wideTemperature 200 C (392 F)Frequency 371 kHzProcess Time 5 secondsEqu…

-

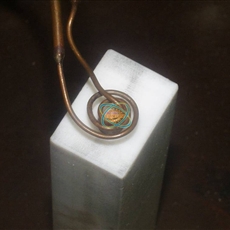

induction soldering brass

Soldering brass Objective To solder a brass end cap to a series of copper tubes Material Preassembled heat exchanger with copper tubes and 2 brass end caps 2.36” (60mm) OD, 0.08” to 0.12” (2 to 3mm) thick at both ends, liquid solder Temperature 30…

-

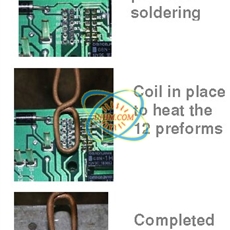

induction soldering circuit boards

Soldering circuit boards Objective To heat post, lead or lead-free solder preforms for various circuit board soldering applications.Material Upper and lower circuit boards, small and large lead or lead free preforms.Temperature < 700 F (371C) depending …

-

induction soldering brass and copper

Soldering brass and copper Objective To heat brass and copper for soldering application on medical equipmentMaterial Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder ringsTemperature 3…

-

induction soldering fabric to kovar tip

Soldering fabric to kovar tip Material Kovar cone, base 3/8” (9.5mm) dia, cone 3/8” (9.5mm) high, solderTemperature 300 F (149 C)Frequency 242 kHzEquipment • Power of 3.2 kW induction heating system, equipped with a remote workhead containing one 1.2μF…

-

induction soldering connectors together

Soldering connectors together Objective Soldering two connectors simultaneously to a tin plated copper ground plateMaterial Tin plated copper ground plate 4” x 1.75” (101.6mm x 44.45mm), 2 connectors, one with12 pins & one with 4 pins and 60/40 solde…

-

induction soldering stainless steel

Soldering stainless steel Objective Heat Stainless steel connector for soldering application in automotive wire harness manufacturingMaterial Stainless steel connector 1.57” (40mm) long, 0.6” (15mm) OD & 0.4” (10mm) thick. Lead free solderTemperatur…

-

induction soldering led to aluminum housing

Soldering LED to aluminum housing Objective Heat an aluminum spotlight housing to solder an LED assembly to the inside baseMaterial LED housing with copper plug, aluminum spotlight housing 5” (127mm) dia at top, 1.25” (31.75mm) dia at base, temperature s…

-

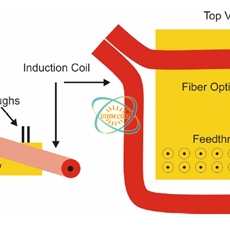

induction soldering glass feedthroughs

Soldering Glass Feedthroughs Objective Heat a kovar fiber optic housing with glass feed-throughs to 400F (204.4C) within 20 seconds for a soldering application, to form a hermetic seal Material Kovar housing with 18 glass feed-throughs, solder preformsand …