Surface Hardening of Steels Class:Induction Heating Tech Article

Surface Hardening of Steels Class:Induction Heating Tech Article Intro: Selective hardening is applied because of one or more of the following reasons:(1) Parts to be heat-treated are so large that conventional furnace heating and quenching becomeimpractical and uneconomical - examples are large gears, large rolls and dies;(2)…

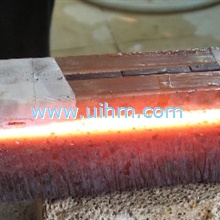

INDUCTION SURFACE HARDENING OF STEEL Class:Induction Heating Tech Article

INDUCTION SURFACE HARDENING OF STEEL Class:Induction Heating Tech Article Intro: High-level surface heating of a thermo technically massive body, when the cooling of the surface to be hardened happens due to abstraction of heat into the body so that the hardening medium is not required, is of both practical and theoretical interest. Ti…

Induction Heating System Topology Review Class:Induction Heating Tech Article

Induction Heating System Topology Review Class:Induction Heating Tech Article Intro: All IH (induction heating) applied systems are developed using electromagnetic induction whichwas first discovered by Michael Faraday in 1831. Electromagnetic induction refers to the phenomenonby which electric current is generated in a closed circuit by t…

induction heating of the aluminum wire before isolation Class:Induction Heating Tech Article

induction heating of the aluminum wire before isolation Class:Induction Heating Tech Article Intro: Manufacturing of self-bearing insulated cable includes the operation of heating of continuously moving aluminum conductons to temperature 80-120 C prior to application of polyethylene isolation.

Induction Heat Staking: insert metal into plastic Class:Induction Heating Tech Article

Induction Heat Staking: insert metal into plastic Class:Induction Heating Tech Article Intro: Simultaneous HeatStaking of ThreeSteel InsertsThere are many plastic moldingapplications that require anassembly with two or threeinserts. By simultaneouslyheating the inserts with inductionin a multi-position coil, theinserts can be pushed into thepart at…

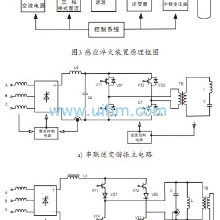

High Frequency Induction Heating Class:Induction Heating Tech Article

High Frequency Induction Heating Class:Induction Heating Tech Article Intro: IntroductionSolid state converters for induction heating are built with different types of switches depending onfrequency range: thyristors for frequencies up to about 10 kHz, IGBTs up to about 100 kHz andPowerMOS up to about 400 kHz. IGBTs have several st…

Induction Brazing Turbine Blades Class:Induction Heating Tech Article

Induction Brazing Turbine Blades Class:Induction Heating Tech Article Intro: Process The UIHM ABS Mark 2 with a vacuum level of <510-4 torr was used for the testing. A specially designed induction coil was used to provide optimal heating (approximately 80% energy efficiency) to the braze joint area. The temperature of the joint …

What Is Induction Heating Class:Induction Heating Tech Article

What Is Induction Heating Class:Induction Heating Tech Article Intro: Clean and fast heat being supplied to the heated workpiece meets the considerably increased requirements with regard to environmental protection. The surroundings is not exposedto any thermal and atmospheric pollution. The particular advantage of this proc…

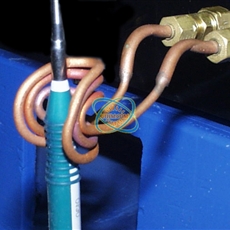

Base Induction Coil Design and Theory Class:Induction Coils Design

Base Induction Coil Design and Theory Class:Induction Coils Design Intro: Induction coil is the key point of leading induction heating machine work successfully.

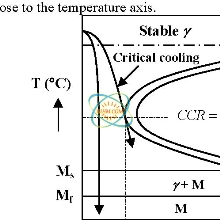

Heat Treatment of Steels Class:Induction Heating Tech Article

Heat Treatment of Steels Class:Induction Heating Tech Article Intro: Heat Treating is the process of heating and cooling a steel to obtain desired properties. Various types of heat treatment processes are used to change the following properties or conditions of the steel: - Improve the toughness - Improve the machinabilit…