Induction Heating System Topology Review

2013/4/8 Views

All IH (induction heating) applied systems are developed using electromagnetic induction which

was first discovered by Michael Faraday in 1831. Electromagnetic induction refers to the phenomenon

by which electric current is generated in a closed circuit by the fluctuation of current in

another circuit placed next to it. The basic principle of induction heating, which is an applied form

of Faraday’s discovery, is the fact that AC current flowing through a circuit affects the magnetic

movement of a secondary circuit located near it. The fluctuation of current inside the primary circuit

provided the answer as to how the mysterious current is generated in the neighboring secondary

circuit. Faraday’s discovery led to the development of electric motors, generators, transformers,

and wireless communications devices. Its application, however, has not been flawless. Heat loss,

which occurs during the induction heating process, was a major headache undermining the overall

functionality of a system. Researchers sought to minimize heat loss by laminating the magnetic

frames placed inside the motor or transformer. Faraday’s Law was followed by a series of more

advanced discoveries such as Lentz’s Law. This law explains the fact that inductive current flows

inverse to the direction of changes in induction magnetic movement.

Heat loss, occurring in the process of electromagnetic induction, could be turned into productive

heat energy in an electric heating system by applying this law. Many industries have benefited

from this new breakthrough by implementing induction heating for furnacing, quenching, and welding.

In these applications, induction heating has made it easier to set the heating parameters without

the need of an additional external power source. This substantially reduces heat loss while

maintaining a more convenient working environment. Absence of any physical contact to heating

devices precludes unpleasant electrical accidents. High energy density is achieved by generating

sufficient heat energy within a relatively short period of time.

The demand for better quality, safe and less energy consuming products is rising. Products using

IH include electronic rice cookers and pans. Safe, efficient and quick heating appliances attract

more customers. This document describes induction heating, power systems, and IH applications.

was first discovered by Michael Faraday in 1831. Electromagnetic induction refers to the phenomenon

by which electric current is generated in a closed circuit by the fluctuation of current in

another circuit placed next to it. The basic principle of induction heating, which is an applied form

of Faraday’s discovery, is the fact that AC current flowing through a circuit affects the magnetic

movement of a secondary circuit located near it. The fluctuation of current inside the primary circuit

provided the answer as to how the mysterious current is generated in the neighboring secondary

circuit. Faraday’s discovery led to the development of electric motors, generators, transformers,

and wireless communications devices. Its application, however, has not been flawless. Heat loss,

which occurs during the induction heating process, was a major headache undermining the overall

functionality of a system. Researchers sought to minimize heat loss by laminating the magnetic

frames placed inside the motor or transformer. Faraday’s Law was followed by a series of more

advanced discoveries such as Lentz’s Law. This law explains the fact that inductive current flows

inverse to the direction of changes in induction magnetic movement.

Heat loss, occurring in the process of electromagnetic induction, could be turned into productive

heat energy in an electric heating system by applying this law. Many industries have benefited

from this new breakthrough by implementing induction heating for furnacing, quenching, and welding.

In these applications, induction heating has made it easier to set the heating parameters without

the need of an additional external power source. This substantially reduces heat loss while

maintaining a more convenient working environment. Absence of any physical contact to heating

devices precludes unpleasant electrical accidents. High energy density is achieved by generating

sufficient heat energy within a relatively short period of time.

The demand for better quality, safe and less energy consuming products is rising. Products using

IH include electronic rice cookers and pans. Safe, efficient and quick heating appliances attract

more customers. This document describes induction heating, power systems, and IH applications.

Down Attachment

- DownloadAttach1: induction heating system topology review.PDF Clicks

Good

Bad

Related Download

parallel resonance circuit of 15KW to 110kw medium frequency induction heater

How to design induction coils yourself(DIY)

Induction welding steel pipes

what is Furnace Brazing

induction heating for cars overview of applied automotive applications

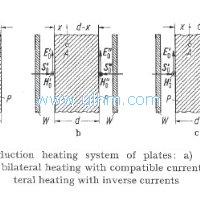

Induction Heating of Flat Objects

hardening induction coil

Solid State Technology of Induction Heating