Induction Heat Staking: insert metal into plastic

2013/4/8 Views

Simultaneous Heat

Staking of Three

Steel Inserts

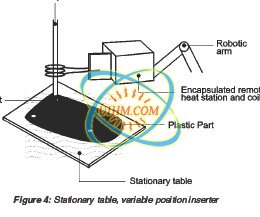

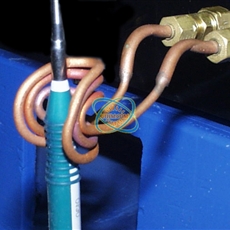

There are many plastic molding

applications that require an

assembly with two or three

inserts. By simultaneously

heating the inserts with induction

in a multi-position coil, the

inserts can be pushed into the

part at the same time, optimizing

throughput and yield. An

automotive door handle required

three steel inserts to be placed

in three separate locations on

the handle. All three locations

were on different plains, but

were inserted from the same

side. The steel inserts are

relatively easy to heat with

induction energy, so a multiposition

coil designed for the

same hole positions as the

inserts on the handle will heat

the three steel parts to 375°F in

2 seconds. The coil is in a single

plane and the insert push rods

are designed to correctly place

each insert into the door handle

on a five-second cycle time.

These steel inserts have a 0.5”

diameter flange which has to

seat on the door handle, but not

melt into the surface. By

designing the coil correctly and

properly positioning the part in

the coil, the body of the insert

can be heated to a higher

temperature than the flange.

Staking of Three

Steel Inserts

There are many plastic molding

applications that require an

assembly with two or three

inserts. By simultaneously

heating the inserts with induction

in a multi-position coil, the

inserts can be pushed into the

part at the same time, optimizing

throughput and yield. An

automotive door handle required

three steel inserts to be placed

in three separate locations on

the handle. All three locations

were on different plains, but

were inserted from the same

side. The steel inserts are

relatively easy to heat with

induction energy, so a multiposition

coil designed for the

same hole positions as the

inserts on the handle will heat

the three steel parts to 375°F in

2 seconds. The coil is in a single

plane and the insert push rods

are designed to correctly place

each insert into the door handle

on a five-second cycle time.

These steel inserts have a 0.5”

diameter flange which has to

seat on the door handle, but not

melt into the surface. By

designing the coil correctly and

properly positioning the part in

the coil, the body of the insert

can be heated to a higher

temperature than the flange.

Down Attachment

- DownloadAttach1: Induction Heat Staking.pdf Clicks

Good

Bad