induction heating of insert coat hanger Type:

induction heating of insert coat hanger Type:

Class: Induction JointingIntro: Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduce

induction hardening knife Type:

induction hardening knife Type:

Class: Induction HardeningIntro: Induction hardening is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is

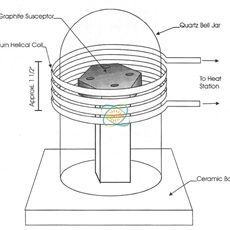

induction brazing CPU station Type:

induction brazing CPU station Type:

Class: HF Induction BrazingIntro: Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction

medium frequency induction melting solder splash(tin dross) Type:

medium frequency induction melting solder splash(tin dross) Type:

Class: Induction MeltingIntro: Induction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.UIHM Induction Melting Furnace provides very efficient & time saving melting of metals f

induction brass solder for copper pipe Type:

induction brass solder for copper pipe Type:

Class: HF Induction Brass SolderIntro: Induction Brass brazing has been applied in various important fields such as the automotive, aviation, electrotechnical and white goods industries. It includes brazing of aluminum, brass, copper, copper alloys, iron and cast iron, steel and stainless stee

induction brazing diamond segment Type:

induction brazing diamond segment Type:

Class: HF Induction BrazingIntro: Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction

induction heating drill pipe by twin coils Type:

induction heating drill pipe by twin coils Type:

Class: Induction JointingIntro: Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an

induction hardening steel pipe Type:

induction hardening steel pipe Type:

Class: Induction HardeningIntro: Induction hardening is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is

induction forging steel rod (steel bar) Type:

induction forging steel rod (steel bar) Type:

Class: MF Induction ForgingIntro: Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 C (2,010 F) and 1,200 C (2,190 F) to increase their malleability and aid flow in the f

induction heating shears Type:

induction heating shears Type:

Class: Induction Thermal TreatmentIntro: Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship