induction preheaing wire online Type:

induction preheaing wire online Type:

Class: Induction Tempering or PreheatingIntro: UIHM Induction is also present in a various of industries for preheating—primarily the automotive, cable and wire, electrotechnical, and tube and pipe industries. In many cases, our induction preheating solutions are integrated into production lines. Usin

Tilting Melting Platinum Furnace Type:

Tilting Melting Platinum Furnace Type:

Class: Rare Metals MeltingIntro: Tilting Melting Platinum FurnaceInduction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.UIHM Induction Melting Furnace provides very efficient &

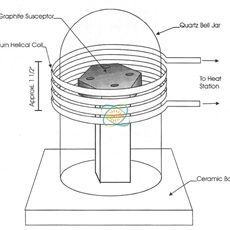

Medium frequency vacuum melting furnace Type:

Medium frequency vacuum melting furnace Type:

Class: Rare Metals MeltingIntro: Medium frequency vacuum melting furnaceInduction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.UIHM Induction Melting Furnace provides very efficien

induction forging copper pipe (IGBT-100KW-10-30KHz) Type:

induction forging copper pipe (IGBT-100KW-10-30KHz) Type:

Class: MF Induction ForgingIntro: Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 C (2,010 F) and 1,200 C (2,190 F) to increase their malleability and aid flow in the f

MF-HF induction Evaporation of zinc sulfide materials Type:

MF-HF induction Evaporation of zinc sulfide materials Type:

Class: Other Induction ApplicationsIntro: Induction heating is widely used for Evaporation of various materials.high frequency induction Evaporation of zinc sulfide materialsmedium frequency induction Evaporation of zinc sulfide materials

induction quenching axle by UM medium frequency induction heaters Type:

induction quenching axle by UM medium frequency induction heaters Type:

Class: HF Induction QuenchingIntro: Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is

High frequency induction evaporation coating and painting Silica-plated Type:

High frequency induction evaporation coating and painting Silica-plated Type:

Class: Other Induction ApplicationsIntro: Our UM-60AB-HF high frequency induction heating machine can be used for induction evaporation coating and induction painting Silica-plated, it will bring a quicker speed and safe work environment.High frequency induction evaporation coating(IGBT-60KW-30KH

induction forging steel rod (steel bars) by UM-250AB-MF Type:

induction forging steel rod (steel bars) by UM-250AB-MF Type:

Class: MF Induction ForgingIntro: Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 C (2,010 F) and 1,200 C (2,190 F) to increase their malleability and aid flow in the f

various of induction melting furnace Type:

various of induction melting furnace Type:

Class: Induction MeltingIntro: Induction melting is the process to melt the ferrous and non-ferrous metals for forming applications, tools & component casting and percious metal melting etc.UIHM Induction Melting Furnace provides very efficient & time saving melting of metals f

induction surface quenching for axle Type:

induction surface quenching for axle Type:

Class: HF Induction QuenchingIntro: Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship