-

Keywords"design",total

57 records

-

induction quenching with custom-design inductor

Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is u…

-

how to design an optimal induction coil

Typically, when the total length of the induction coil is shorter, the output frequency of induction coil will be higher, and the heating speed will be faster.But each type of induction heating machine has anoptimal frequency value, only when the frequency…

-

inductor (induction coil) designing

It is within the inductor that the varying magnetic field required for induction heating is developed, through the flow of alternating current. (Induction Coil) design is therefore one of the most important aspects of the overall induction heating machine.…

-

how to design induction coils yourself(diy)

The induction heaters heating effect and output power will be influenced by shape, size, turns of induction coils, material and heating area of work-piece, turn ratio of secondary coil, coupling degree between induction coil and work-piece. A well designed…

-

base induction coil design and theory

Induction coil is the key point of leading induction heating machine work successfully.

-

induction coil design and fabrication

The inductor is similar to a transformer primary, and the workpiece is equiva-lent to the transformer secondary . Therefore, several of the charac-teristics of transformers are useful in the development of guidelines for coil design.One of the most importa…

-

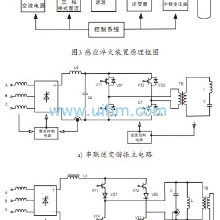

high,medium frequency induction heating quenching furnace engineering design method

0 IntroductionHigh, medium frequency induction heating power supply unit is used for the heat treatment of machine metal parts, widely used in the automobile and other machinery manufacturing industry. The practice shows that the induction heat treatment i…