Inductor (induction coil) designing

Views Send Enquiry

It is within the inductor that the varying magnetic field required for induction heating is developed, through the flow of alternating current.

It is within the inductor that the varying magnetic field required for induction heating is developed, through the flow of alternating current.

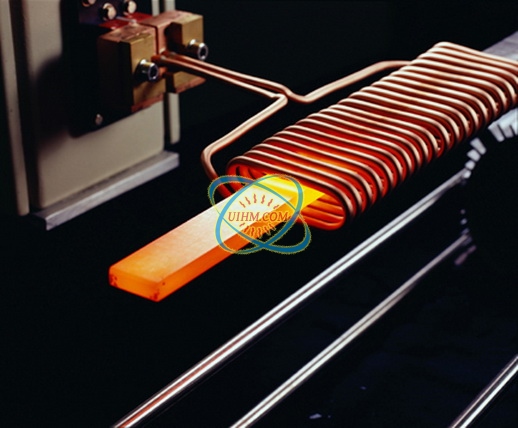

(Induction Coil) design is therefore one of the most important aspects of the overall induction heating machine. A well-designed inductor provides the proper heating pattern for your part and maximizes the efficiency of the induction heating power supply, while still allowing easy insertion and removal of the part.

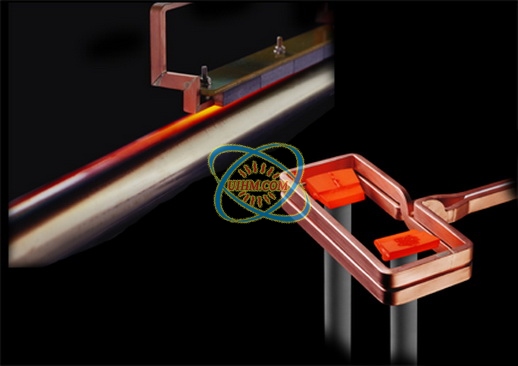

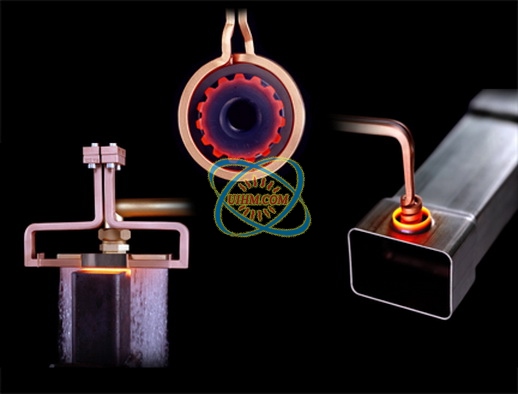

The inductor does not have to be shaped in a helix. With the right design, it is possible to heat conductive materials of any size and form, and also possible to

heat only the portion of material required. It is even possible to heat different zones

of the part at the same or different temperatures by means of a proper design of the inductor geometry. Temperature uniformity within your part is achieved through

correct inductordesign. The most effective uniformity can be achieved in round parts. Due to the nature of electrical current path flow, parts with sharp edges could

preferentially heat in those areas if the proper inductor design is not used.

Coupling Efficiency

There is a proportional relationship between the amount of current flow and distance between the inductor and part. Placing the part close to the inductor increases the flow of current and the amount of heat induced in the part. This relationship is referred to as the coupling efficiency of the inductor.

|

|

|

|

|

|

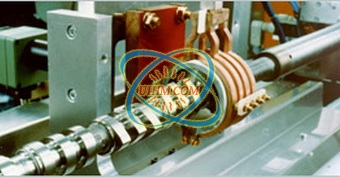

Basic Construction

Inductors (induction coil) are often made of copper tubing – a very good conductor of heat and electricity – with a diameter of 1/8" to 3/16"; larger copper coil assemblies are made for applications such as strip metal heating and pipe heating. Inductors are usually cooled by circulating water, and are most often custom-made to fit the shape and size of the part to be heated. So inductors can have single or multiple turns; have a helical, round or square shape; or be designed as internal (part inside inductor) or external (part adjacent to inductor).

Induction Coils_03

Induction Coils_02

Induction Coils_06

Induction Coils_04

Induction Coils_05

Induction Coils_01

Induction Coils_07

Induction Coils_10

Induction Coils_11

Induction Coils_09

Related Content

custom-build double induction coil

special induction coil for quenching

air cooled pancake induction coils

what is skin effect principle (magnetic force around induction coil)

custom-build solenoid induction coils with screw fixing for textile machine

induction Coil Gallery

induction coil for forging steel plate

heating source simulation by 100KW induction heater with solid induction coil

Hot

induction coil for forging steel plate

air cooled pancake induction coils

heating source simulation by 100KW induction heater with solid induction coil

customized induction coil for forging works

induction coil for forging steel rod

producing induction coils for induction forging works

customized induction coils for annealing works

induction coil for heating preservation

Newest Comment

No Comment

Post Comment