-

Keywords"n",total

3020 records

-

competitive advantages of uihm

ODM AcceptedOEM AcceptedWell and High Quality ControlPrompt DeliveryNew ProductCustomer s Design and Logo are WelcomeCompetitive PricesEarth-friendly ProductsIn a Variety of DesignSmall Order Acceptable

-

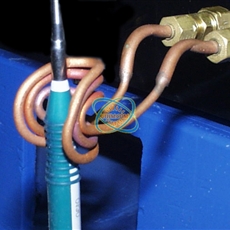

induction heating of the aluminum wire before isolation

Manufacturing of self-bearing insulated cable includes the operation of heating of continuously moving aluminum conductons to temperature 80-120 C prior to application of polyethylene isolation.

-

what is induction heating and induction heating principle?

induction heatingWhat is Induction Heating? Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents (also called Foucault currents) are generated within the metal an…

-

induction heat staking: insert metal into plastic

Simultaneous HeatStaking of ThreeSteel InsertsThere are many plastic moldingapplications that require anassembly with two or threeinserts. By simultaneouslyheating the inserts with inductionin a multi-position coil, theinserts can be pushed into thepart at…

-

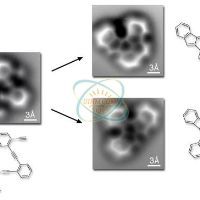

first-ever high-resolution images of a molecule as it breaks and reforms chemical bonds

Almost as clearly as a textbook diagram, this image made by a noncontact atomic force microscope reveals the positions of individual atoms and bonds, in a molecule having 26 carbon atoms and 14 hydrogen atoms structured as three connected benzene rings. Cr…

-

high frequency induction heating

IntroductionSolid state converters for induction heating are built with different types of switches depending onfrequency range: thyristors for frequencies up to about 10 kHz, IGBTs up to about 100 kHz andPowerMOS up to about 400 kHz. IGBTs have several st…

-

what is the hs code of induction heating machine

851440****(8514400000/8514400090). DescriptionOther equipment for the heat treatment of materials by induction or dielectric loss. Goods ever classified under this HS code(usually 8514400000~8514400090)intermediate frequency interaction smelting furnace ,i…

-

induction brazing turbine blades

Process The UIHM ABS Mark 2 with a vacuum level of <510-4 torr was used for the testing. A specially designed induction coil was used to provide optimal heating (approximately 80% energy efficiency) to the braze joint area. The temperature of the joint …

-

induction melting gold with um induction heater

Overview Melting metals with solid state RF induction heating is usually accomplished by heating the metal in a crucible made from a non-conductive refractory material. The charge of metal within the crucible is melted down to liquid form.This process is c…

-

what is induction heating

Clean and fast heat being supplied to the heated workpiece meets the considerably increased requirements with regard to environmental protection. The surroundings is not exposedto any thermal and atmospheric pollution. The particular advantage of this proc…