-

Keywords"n",total

3020 records

-

induction brazing diamond drill

Objective To braze diamond inserts to a steel drilling ringMaterial • steel ring and diamond inserts• Braze shim preform• FluxTemperature 1300 – 1350 (700 – 730) F (C)Frequency 68 kHzEquipment Power of 35 kW, induction heating system, equipp…

-

induction brazing carbide tool

Objective Braze carbide rotary file assemblies with uniform concentricity in an aerospace application Material • Carbide blank • High speed steel shank • Temperature indicating paint • Braze shim and black flux Temperature 1400F (760C) Frequency …

-

induction brazing cutting tool

Objective To braze cone and shaft for a cutting tool Material Customer supplied parts Temperature indicating paint Braze preforms Temperature 1300 – 1400 F (704 – 760 C) Frequency 235 kHz Equipment Power of 6 kW, 150-400 kHz induction h…

-

induction brazing copper fittings

Objective Copper ‘tees’ and ‘ells’ are to be brazed to the aluminum body of a refrigeration valveMaterial customer’s valvecopper fittingsbrazeTemperature 2550 F (1400C)Frequency 285 kHzEquipment Power of 15KW induction heating system including a workh…

-

induction brazing carbide tips

Objective Attaching carbide cutters to a steel meat cutter impeller Material carbide blocks; steel shank fitting Temperature 1400 F (760 C) Frequency 219 kHz Equipment Power of 30kW induction heating systems including: Induction heating coil …

-

induction brazing brass fitting to copper air lines

Objective To braze brass end-connectors to copper tubes used in aircraft assembly air linesMaterial brass end connectors, copper tubes of different diametersTemperature 1400 F 750CFrequency 350 kHzEquipment Power of 6KW induction heating system, including …

-

induction brazing water faucets

Objective Brazing several brass and copper assemblies used in water faucetsMaterial braze, white fluxTemperature 1350 F 730CFrequency 160 or 277 kHz (coil dependant)Equipment Power of 15kW induction heating system, remote work head with two 1μF capacitors…

-

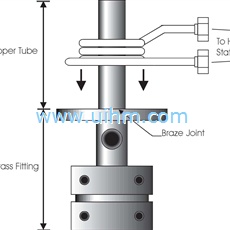

induction braze copper tube to brass fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300F…

-

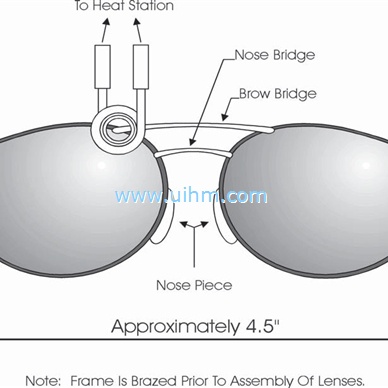

induction brazing eyeglass frame assembly

Objective Produce repeatable braze joints for the assembly of eyeglass frames. Induction heating is to be used to achieve quality braze joints on the nose bridge, brow bridge and nose piece. Brazing is to be done at 1300F with approximately 3-5 seconds al…

-

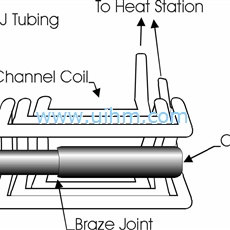

induction brazing copper tube

Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″ fitting in less than 10 seconds. Heating must take place in a channel type coil to allow for easy loading of parts. Material Copper Tubing and Fitting with Braze and Stay Silv White…