-

Keywords"n",total

3020 records

-

induction annealing stress relieving

STRESS RELIEVING,NORMALISING AND ANNEALINGStress RelievingStress relieving is applied to both ferrous and non-ferrous alloys and is intended to remove internal residual stresses generated by prior manufacturing processes such as machining, cold rolling and…

-

induction hardening and flame hardening

WHAT ARE THE TREATMENTS? Induction hardening and flame hardening are methods for hardening the surfaces of components, usually in selected areas, by the short-time application of high-intensity heating followed by quenching. The heating and hardening eff…

-

induction hardening and tempering of tools

WHAT ARE THE STEELS?Tool and die steels are covered in BS 4659:1989, although both American nomenclature and a variety oftrade names are also in use. Available in high-quality grades, these specifically-designed steels can be groupedbroadly according to t…

-

induction de-bonding stainless steel

Objective To separate bonded stainless steel / carbon fiber assemblies by heating tang, softening the adhesive bond Material Stainless steel and carbon fiber inserts Temperature 300 F (149C) Frequency 200 kHz Equipment • Power of 6kW induction heating…

-

induction bonding plastic sleeve to stainless steel handle

Objective Heating end of a stainless steel handle with a plastic sleeve coated with heat adhesive for a bonding applicationMaterial 1” (25mm) OD stainless steel handle 0.30” (7.6) thick covered with a plastic sleeve that is coated with a heat adhesive be…

-

induction debond rubber seal from steel

Objective Debond a fluorocarbon rubber seal from a carbon steel oil seal Material 4” (10.2cm) OD carbon steel oil seal with a fluorocarbon rubber seal Temperature 1200 F (649 C) Frequency 179 kHz Equipment • Power of 6kW induction heating system, equi…

-

induction bonding gasket to nut

Objective To heat a steel sombrero nut prior to gasket bonding Material • Steel sombrero-shaped nut approx. 2” (50.8mm) diameter, 2” (50.8mm) in height • gasket Temperature 350 F (176 C) Frequency 266 kHz Equipment • Power of 6kW induction heating…

-

induction brazing thin walled tube

Objective Braze a NI-SPAN-C alloy tube to a steel cap in a hydrogen atmosphere Material NI-SPAN-C alloy tube (5mm) dia, steel cap (7mm) dia, (7mm) long, nickel braze, quartz tube and hydrogen Temperature 1875 F (1024 C) Frequency 313 kHz Equipment • P…

-

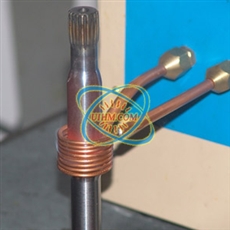

induction brazing piston valve

Objective Brazing a steel piston valve assembly Material Steel piston valve 4.5” dia (11.43cm), tungsten carbide plate and braze Temperature 1350 F Frequency 91 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhead c…

-

induction brazing brass faucet

Objective Brazing two joints on a brass bathroom faucet assembly Material Brass bathroom fittings 1” OD, brazing rings, flux Temperature 1148 F (620 C) Frequency 90 kHz Equipment • Power of 90kW induction heating system, equipped with a remote workhe…