-

Keywords"n",total

3020 records

-

induction forging valve

A superior alternative to furnace heating, induction heating provides faster, more efficient heat in forging applications. The process relies on electrical currents to produce heat within the part that remains confined to precisely targeted areas. High pow…

-

induction forging rod steel

A superior alternative to furnace heating, induction heating provides faster, more efficient heat in forging applications. The process relies on electrical currents to produce heat within the part that remains confined to precisely targeted areas. High pow…

-

induction forging steel horse shoes

Objective To heat a strip of 1025 steel to 1800 oF prior to a forging process for the production of horse shoes. Presently, blanks are cut and heated in a gas fired oven and then forged in the press. With an induction coil in place, the steel would be fed …

-

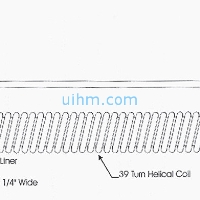

flexible induction coil with magnetic core

flexible induction coil with magnetic core

-

induction bending pipeline for elbow forming

induction heating is widely used for bending big gas or oil pipelineinduction bending pipeline

-

induction tempering by uhf

Induction Tempering are widespread use in the automotive and automotive-supply industries. In fact, induction tempering can be performed on all hardened components—bars, joints, shafts, etc. induction tempering by UHF

-

uhf induction tempering

Induction Tempering are widespread use in the automotive and automotive-supply industries. In fact, induction tempering can be performed on all hardened components—bars, joints, shafts, etc. UHF induction tempering

-

uhf induction annealing

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.UHF induction annealing

-

ultra high frequency induction annealing

Induction Annealing is a heat treatment in which material is exposed to an elevated temperature and slowly cooled. Induction Annealing of the material changes physical properties of the material such as strength and hardness.ultra high frequency induction …

-

uhf induction brass solder

UIHM induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.UHF induction brass solderUHF induction brass soldering