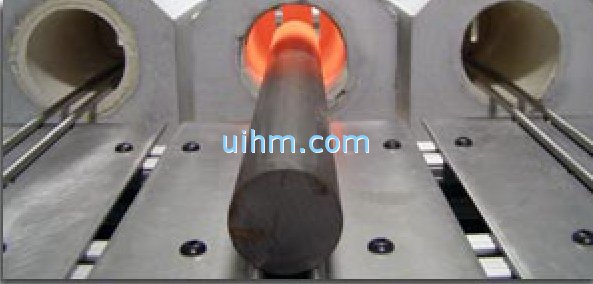

induction forging rod steel

Views Send Enquiry

A superior alternative to furnace heating, induction heating provides faster, more efficient heat in forging applications. The process relies on electrical currents to produce heat within the part that remains confined to precisely targeted areas. High power density means extremely rapid heating, with exacting control over the heated area.

Recent advances in solid-state technology have made induction heating a remarkably simple and cost-effective heating method.

Benefits of using induction forging are:

. Rapid heating for improved productivity and higher volumes

Precise, even heating, of all or only part of the forging

. A clean, non-contact method of heating

. Safe and reliable – instant on, instant off heating

. Cost-effective, reduces energy consumption compared to other heating methods

. Easy to integrate into production cells

. Reduced scaling

induction forging rod steel

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

induction heating steel plate by pancake induction coil

induction heating steel knife

induction heating steel pipes by water cooled flexible induction coil and 120KW RF induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction annealing 1mm to 2mm steel wire online by 200KW MF induction heater

induction heating steel plate

Hot

MF auto feed induction forging system

MF induction heater for forging work

induction forging long steel rods by MF machine

auto feed induction forging system

customized MF induction heater for forging steel rods

induction forging steel rods with series connection induction coil

induction forging steel rods by MF induction heater

induction forging steel rods

Newest Comment

No Comment

Post Comment