-

Keywords"and",total

198 records

-

quick induction brazing for pipe and pot

Induction Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 500 C and below the melting temperature of parent materials being joined.Induction …

-

handheld transformer with flexible induction coil

handheld transformer with flexible induction coilhandhold head induction heating machineBase Induction Coil Design and Theory Induction Coil Design and Fabrication

-

induction welding for hdmi and usb

1 high-frequency welding 1.1 principle: the principle of electromagnetic effects in the alternating magnetic field Metal inside the material rapidly induced significant vortex Induction heating equipment. 1.2 Advantages: energ…

-

induction brazing and shrinking fit for big rotors

induction brazing and shrinking fit for big rotors

-

theory and examples of ac resonant charging,

RESONANT CHARGING The connection of a Tank capacitor across an inductively ballasted supply creates a resonant circuit. The resonant frequency of this arrangement is determined by the valu…

-

induction melting gold and silver

Melting Gold and Silver Everything for Gold and Silver Melting, it used to be that when melting gold, people used a blow torch, then a torch, then an electric melter and then an induction melter. Whatever your choice, we have the torch, the electric melter…

-

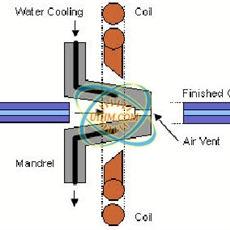

induction heating brass mandrel die

Heating brass mandrel die Objective Water-cooled brass mandrel die, nylon LDPE catheter, “K” type thermocouple and temperature controller. Material materials, supplies involved in the application Temperature 400F (204C) Frequency 325kHz Equipment…

-

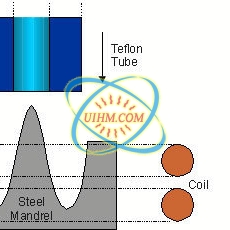

induction heating steel mandrel tip

Heating steel mandrel tip Objective Heat a water-cooled steel mandrel to 700F (371C) to form a high quality Teflon catheter tip.Material Teflon catheter tubing, mandrel assemblyTemperature 600-700F (315-371C)Frequency 376 kHzEquipment • Power of 10kW indu…

-

induction soldering brass and copper

Soldering brass and copper Objective To heat brass and copper for soldering application on medical equipmentMaterial Brass ring, brass and copper pieces 5.11” (130mm) long, 4.3” (110mm) OD & 0.3” (7mm) at thickest point and solder ringsTemperature 3…

-

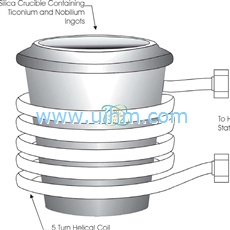

induction melting ticonium and nobilium

Melting Ticonium and Nobilium Objective: Crucible melting of Ticonium and Nobilium ingots within a period of 45 seconds. Four ingots of Nobilium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Ticonium is placed in a crucible (…