Induction Welding for HDMI and USB

Views Send Enquiry

1 high-frequency welding

1.1 principle: the principle of electromagnetic effects in the alternating magnetic field

Metal inside the material rapidly induced significant vortex

Induction heating equipment.

1.2 Advantages: energy saving, and no high-voltage electric shock hazard, fast heating, volume

Small size, light weight, easy to install.

Disadvantages: power is not easy to control (vehicle positioning requires high).

1.3 Application examples:

High-frequency welding industry applications:

★ diamond tools, carbide cutting tools, welding;

★ all kinds of metal steel - steel, steel - copper, copper - copper equivalent metal or different

Kinds of metal high-frequency welding;

★ metal material hardening, annealing, quenching and tempering, tempering and other heat treatment;

★ metal hot forging, heat molding;

★ powder metallurgy sintering and metal smelting;

★ other field that need to be heated to metal;

★ organic coating curing;

★ of monocrystalline's heating stretch;

1.1 principle: the principle of electromagnetic effects in the alternating magnetic field

Metal inside the material rapidly induced significant vortex

Induction heating equipment.

1.2 Advantages: energy saving, and no high-voltage electric shock hazard, fast heating, volume

Small size, light weight, easy to install.

Disadvantages: power is not easy to control (vehicle positioning requires high).

1.3 Application examples:

High-frequency welding industry applications:

★ diamond tools, carbide cutting tools, welding;

★ all kinds of metal steel - steel, steel - copper, copper - copper equivalent metal or different

Kinds of metal high-frequency welding;

★ metal material hardening, annealing, quenching and tempering, tempering and other heat treatment;

★ metal hot forging, heat molding;

★ powder metallurgy sintering and metal smelting;

★ other field that need to be heated to metal;

★ organic coating curing;

★ of monocrystalline's heating stretch;

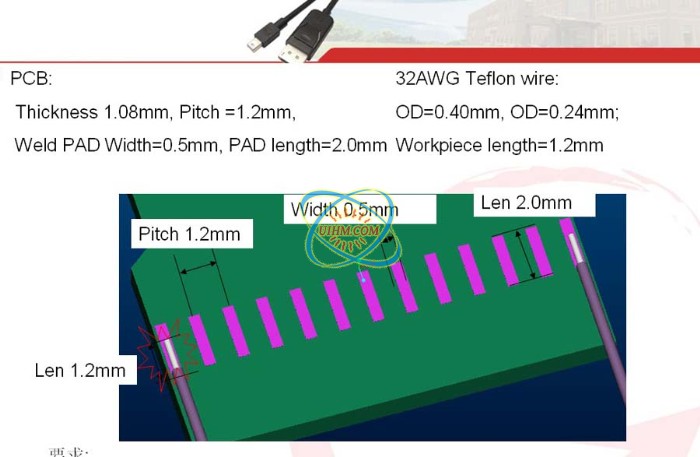

hdmi welding

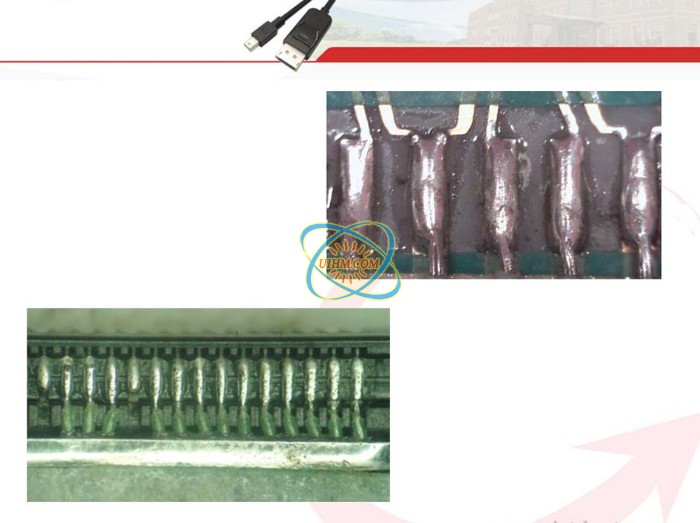

hdmi welding result

Good

Bad

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

high frequency induction welding (HFIW) continuous butt welding of tubes

induction welding automotive stainless plate for Toyato

induction welding drill bit (bore bit or drill pipe or drill rod or cutting pick)

induction welding steel bar

induction welding motor short-curcuit ring by flexible handle induction coil

induction welding motor (generator windings) short-curcuit ring

induction welding phosphor copper rings

induction tin soldering distributor branches

Newest Comment

No Comment

Post Comment