induction brass solder for copper pipes and connectors Type:

induction brass solder for copper pipes and connectors Type:

Class: HF Induction Brass SolderIntro: Induction brass solder will bring a quicker speed and better soldering quality than common methods.induction brass solder 1induction brass solder 2induction brass solder

Grinding Shoe by induction Brazing Type:

Grinding Shoe by induction Brazing Type:

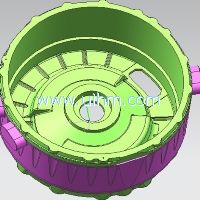

Class: HF Induction BrazingIntro: This application is induction brazing for Grinding Shoe, it brings quick speed and wonderful welding effect. Grinding Shoe by induction BrazingGrinding Shoe

inducton shrinking fit for 2 shells Type:

inducton shrinking fit for 2 shells Type:

Class: Induction Shrink FittingIntro: induction heating is a very good method for shrinking fit work, quick speed, none-contact,environmental protected.shrinking fit for 2 shells

induction brass soldering for pot bottom Type:

induction brass soldering for pot bottom Type:

Class: HF Induction Brass SolderIntro: Induction heating is widely used for brass soldering, its better than common heating ways like gas welding.induction brazing copper scewinduction brass brazing nutinduction brass brazinginduction brass soldering

induction hot fit massive complex shapes Type:

induction hot fit massive complex shapes Type:

Class: Induction Shrink FittingIntro: High-frequency induction heating is successfully used for shrink-fit and renting unique details (bandages, all bore rotors of turbine parts, parts with bore powerful engines, bearing rings, propellers of ships, bore different parts forging equipment, etc.

High frequency induction brazing copper bars for the stator winding Type:

High frequency induction brazing copper bars for the stator winding Type:

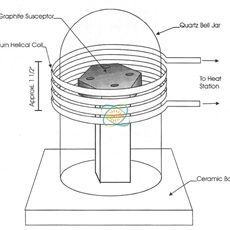

Class: HF Induction BrazingIntro: High frequency induction brazing is an energy-saving technology. High power densities that are implemented in induction heating, allow to rapidly heat the local area to the soldering temperature 600 - 1200 C, at a cost of minimum energy process compared

High frequency induction brazing pipes for copper and iron alloys Type:

High frequency induction brazing pipes for copper and iron alloys Type:

Class: HF Induction BrazingIntro: High frequency induction brazing is an energy-saving technology. High specific power, which are implemented by induction heating to quickly heat the local area to the brazing temperature 600 - 1200 C, spending at the lowest energy in the process compared

High-frequency induction surface hardening working for the steel Type:

High-frequency induction surface hardening working for the steel Type:

Class: Induction HardeningIntro: induction hardening HDTV rotating bodies made with the rotation of hardened parts. Long parts hardened inductor in series with the movement along the axis of the member. Cooling the workpiece immediately after the heating is performed by jets of water or

induction heating automotive chassis Type:

induction heating automotive chassis Type:

Class: Induction Thermal TreatmentIntro: Induction heating has been widely used in automobile industry like automotive chassis heat treatment as bellowinduction heating automotive chassis

induction Zone Heating for Bending Type:

induction Zone Heating for Bending Type:

Class: Induction Thermal TreatmentIntro: induction Zone Heating for BendingInduction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction a

Recommended

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel knife

induction deicing for aircraft carrier,naval vessels, naval craft, naval ships and boats, warship