-

Keywords"carbide tip",total

7 records

-

induction brazing carbide tips

induction brazing carbide tips

-

induction brazing for carbide tips

induction brazing for carbide tips

-

induction brazing carbide tip

Induction Brazing temperature can be controlled from 500 C to 1800 C for most of the brazing applications.UIHM induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.indu…

-

induction brazing carbide tips

Induction brazing and soldering are processes that take advantage of induction heatings ability to deliver rapid localized heating to a particular region of a part.induction Brazing Carbide Tipssaw teeth brazing

-

induction brazing carbide tip

Objective Braze a carbide tip to a 4140 steel cutting tool Material Carbide Isograde C2 & C5 tips, 4140 circular steel cutter, flux and silver braze shim Temperature 1400 F (760 C) Frequency 290 kHz Equipment • Power of 20kW induction heating syst…

-

induction brazing carbide tips

Objective Attaching carbide cutters to a steel meat cutter impeller Material carbide blocks; steel shank fitting Temperature 1400 F (760 C) Frequency 219 kHz Equipment Power of 30kW induction heating systems including: Induction heating coil …

-

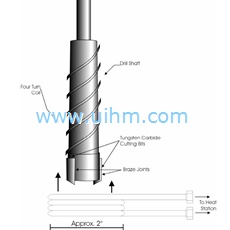

induction brazing carbide tips on drill bits

Objective To braze carbide cutting tips to drill bits ranging in size from 0.5″ to 1.5″ in diameter. The brazing takes place at 1900F and is presently done in 11 seconds for the 0.5″ diameter bit and 39 seconds for the 1.5″ diameter bit. Customer goals…