-

Keywords"pipes",total

70 records

-

induction brass solder for copper pipes and connectors

Induction brass solder will bring a quicker speed and better soldering quality than common methods.induction brass solder 1induction brass solder 2induction brass solder

-

high frequency induction brazing pipes for copper and iron alloys

High frequency induction brazing is an energy-saving technology. High specific power, which are implemented by induction heating to quickly heat the local area to the brazing temperature 600 - 1200 C, spending at the lowest energy in the process compared …

-

induction induction brazing pipes

Induction brazing and soldering are processes that take advantage of induction heatings ability to deliver rapid localized heating to a particular region of a part.induction induction Brazing pipes

-

induction painting spraying for steel pipes

induction Painting spraying for steel pipes

-

high frequency induction brazing steel pipes

auto induction brazing kinfe High Frequency Induction brazing steel pipes High Frequency Induction brazing steel pipes

-

induction brazing of copper pipes

Machine: UM-20AB-UHF induction brazing of copper pipes

-

induction jointing for pipes bottom part

induction jointing for pipes bottom part induction jointing for pipes bottom part

-

induction bending for big pipes

Induction bending

-

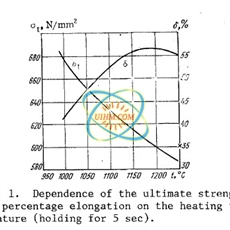

heat treatment with induction heating of within pipes

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat-trea…

-

induction welding steel pipes

Steel welding using induction heating to produce pipelines is found to have lower toughness at the weld junction than the base material, even after a heat treatment which reaustenitises the weld zone. Detailed crystallographic characterisation indicates th…