-

Keywords"Aluminum",total

34 records

-

induction annealing Aluminum lip

Objective Annealing a 1” lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming. Material Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick Temperature 800 F (427 C) Frequency 303 kHz Equi…

-

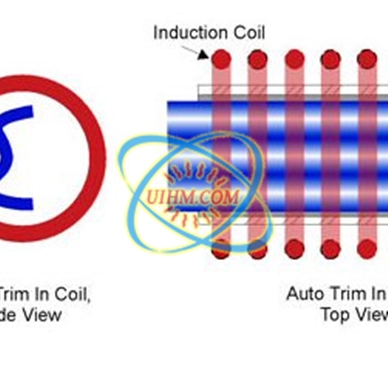

induction heating Aluminum auto trim

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive. Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube Temperature :50…

-

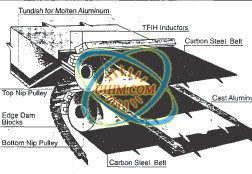

induction heating producing Aluminum

Barmet Aluminum Corporation produces 300 million lbs. of aluminum sheet per year and has plants located inUhrichville, Ohio and Carson City, California. At the plants, scrap and ingots are melted in gas-fired reverberatoryfurnaces and the molten aluminum a…

-

induction heating of the Aluminum wire before isolation

Manufacturing of self-bearing insulated cable includes the operation of heating of continuously moving aluminum conductons to temperature 80-120 C prior to application of polyethylene isolation.