-

Keywords"by",total

372 records

-

induction hardening gear teeth one by one

induction hardening gear teeth one by one

-

induction melting of vacuum furnace by um-25ab-mf

Medium frequency vacuum induction melting furnaceFeature and application:Whole Stainless steel design Horizontal furnace and side opening structure to load samples convenientlyCompact furnace structure, save spaceIGBT module power supply Widely applied in …

-

induction tempering by uhf

Induction Tempering are widespread use in the automotive and automotive-supply industries. In fact, induction tempering can be performed on all hardened components—bars, joints, shafts, etc. induction tempering by UHF

-

induction melting by igbt or scr

Induction melting by IGBT machine will bring a quicker speed and being more energy saving than SCR ones, but IGBT when you are going to melting more than 800KG metal, SCR machine will be a better choice.induction melting by IGBT or SCR

-

molybdenum and tungsten by induction line heating(igbt-300kw-15khz)

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced…

-

induction quenching axle by um medium frequency induction heaters

Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is u…

-

induction forging steel rod (steel bars) by um-250ab-mf

Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 C (2,010 F) and 1,200 C (2,190 F) to increase their malleability and aid flow in the fo…

-

induction heating drill pipe by twin coils

Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an a…

-

grinding shoe by induction brazing

This application is induction brazing for Grinding Shoe, it brings quick speed and wonderful welding effect. Grinding Shoe by induction BrazingGrinding Shoe

-

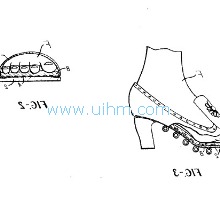

shoe molded by induction heating

Tthis application can be used for model of footwear of any kind, as boots, sandals, shoes, etc., Induction heating will bring a quick and accurate heating effect. shoe molded by induction heating