-

Keywords"UM",total

387 records

-

induction preheating titaniUM rods

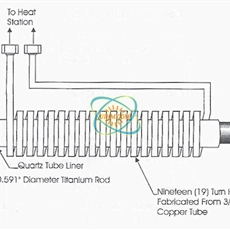

Objective To heat titanium rod blanks prior to forging into a turbine blade. Material Titanium rod blanks 0.591″(15.01mm) OD by 11.8″(299.7mm) long Temperature 2030F(1110C) Frequency 64 kHz Equipment • Power of 45kW induction heating system equipped…

-

induction sealing alUMinUM foil to plastic bottle

Objective To seal a 1.5” (38.1mm) diameter cap with foil to a plastic bottle.Material 1.5” (38.1mm) diameter cap with 1.5” (38.1mm) diameter aluminum seal, plastic bottleTemperature 250-300 F (121-149 C)Frequency 309 kHzEquipment •Power of 6kW inductio…

-

induction coating alUMinUM

Objective To heat an aluminum molding shape in order to activate an adhesive coating prior to applying the vinyl Material Aluminum molding folded from a flat sheet measuring 2″ wide and 0.03″ thick. The final form measures 5/8″ by 1″ Temperature 500F…

-

induction brazing alUMinUM tubing

Objective Heat aluminum for an automotive brazing application Material Aluminum tubing 0.50 (12.7mm) dia, an aluminum boss 1”(25.4mm) long, flux filled braze rings Temperature 1200 F (649 C) Frequency 270 kHz Equipment •Power of 10kW induction heatin…

-

induction brazing plUMbing

Objective A copper-brass fluids union is brazed under constrained conditions (onboard a submarine), where access is limited and flame is not allowed. Material copper and brass plumbing components Temperature 750C (1380 F) Frequency 245 kHz Equipment Po…

-

induction annealing alUMinUM tubing

Objective Annealing aluminum fuel tank fill neck to 650 F (343 C) Material Aluminum fill neck 2.5” (63.5mm) diameter, 14” (35.5cm) long Temperature 650 F (343 C) Frequency 85 kHz Equipment • 40kW induction heating system, equipped with a remote work…

-

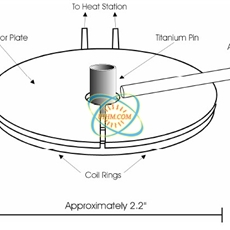

induction annealing alUMinUM lip

Objective Annealing a 1” lip on aluminum cryogenic dewar that has been work hardened during the process of spin forming. Material Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick Temperature 800 F (427 C) Frequency 303 kHz Equi…

-

induction annealing titaniUM fasteners

Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process. Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in length Temperature 1100-145…

-

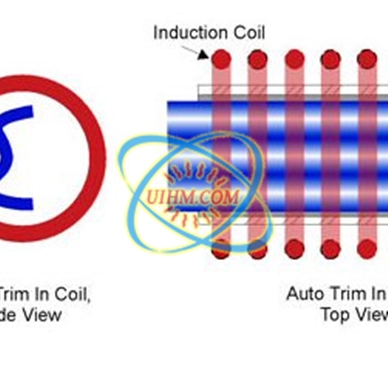

induction heating alUMinUM auto trim

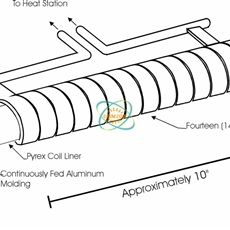

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive. Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube Temperature :50…

-

UM-80ab-hf induction heating machine

Parameters of High Frequency Induction Heating Machines:TypePower SupplyInput CurrentOutput PowerMax. FrequencyInput PowerCooling WaterNormal Size(cm)Net Weight(kg)UM-05A-HF6KVA23A5KW250KHz220VAC, 50Hz, Single Phase>0.2 MPa, 6 L/Min, <40 C 18 X 33 X …