-

Keywords"TitaniUM",total

17 records

-

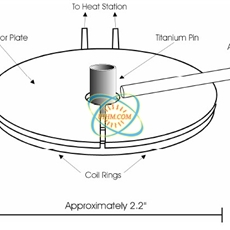

quick induction heating TitaniUM-bars

-

induction melting TitaniUM and nobelium

Objective: Crucible melting of Titanium and Nobelium ingots within a period of 45 seconds.Four ingots of Nobelium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Titanium is placed in a crucible (ID#65045) for heating. Materia…

-

induction heating TitaniUM alloy

induction heating titanium alloy

-

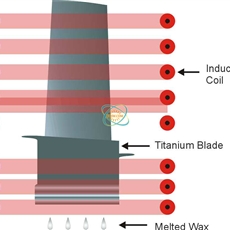

induction heating TitaniUM blade

Heating Titanium Blade Objective Heat a titanium blade to 500F (200C) to melt and drain the wax from inside the blade.Material 4” length (101.6mm) titanium blades with 1.5” x 0.25” (38.1mm x 6.4mm) metering areaTemperature 500F (200C)Frequency 186 kHzEq…

-

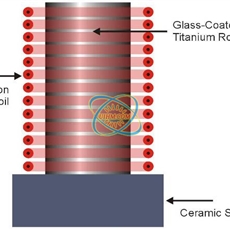

induction hot forming TitaniUM rod

Objective To heat a titanium rod to 1700F (926.7C) within 60 seconds for hot forming. Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) length Temperature 1700F (926.7C) Frequency 70 kHz Equipment • Power of 60kW induction heating system, eq…

-

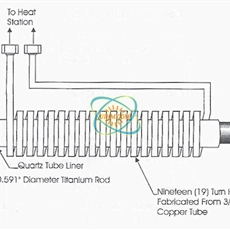

induction preheating TitaniUM rods

Objective To heat titanium rod blanks prior to forging into a turbine blade. Material Titanium rod blanks 0.591″(15.01mm) OD by 11.8″(299.7mm) long Temperature 2030F(1110C) Frequency 64 kHz Equipment • Power of 45kW induction heating system equipped…

-

induction annealing TitaniUM fasteners

Objective Heating a titanium fastener to 1100-1450F (593-788C) for an annealing process. Material 0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7-76.2mm) in length Temperature 1100-145…