-

Keywords"Hardening",total

166 records

-

induction Hardening gear

In recent years, gear manufacturers have gained additional knowledge about how technology can be used to produce quality parts. The application of this knowledge has resulted in gears that are quieter, lighter, and lower cost, and have an increased load-ca…

-

Hardening and tempering of tool and die steels

Tool and die steels are covered in BS 4659:1989,although both American nomenclature and a variety of trade names are also in use. Available in high-quality grades, these specifically-designed steels can be grouped broadly according to their intended applic…

-

surface Hardening of steels

Selective hardening is applied because of one or more of the following reasons:(1) Parts to be heat-treated are so large that conventional furnace heating and quenching becomeimpractical and uneconomical - examples are large gears, large rolls and dies;(2)…

-

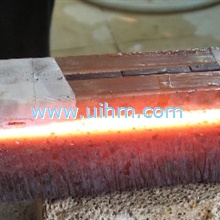

induction surface Hardening of steel

High-level surface heating of a thermo technically massive body, when the cooling of the surface to be hardened happens due to abstraction of heat into the body so that the hardening medium is not required, is of both practical and theoretical interest. Ti…

-

auto induction Hardening

auto induction hardening

-

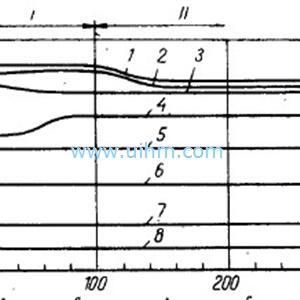

effect of surface Hardening by high frequency induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…