What Is Annealing

Views Send Enquiry

Annealing is a not just a simple process with just one effect and a single result. It is a complex technique that can be carried out in many different ways and at different steps in the manufacturing process to obtain different effects on the metals or components in question. It is a complex and delicate process that involves heating steel to a precise temperature and keeping at this temperature for a stipulated amount of time before cooling it again at a precise rate to achieve more favourable cold working properties and greater softness and machinability.There are many different techniques of this process and when a heated component is brought back to room temperature through cooling inside a furnace it is called a full anneal heat treatment. On the other hand removing the heated component from the furnace after the stipulated period of heating and then allowing it to cool down in open air is called a normalising heat treatment.Annealing takes the metals to a temperature that is above their re-crystallisation temperature. The actual process occurs on a sub molecular level with the actual diffusion of atoms through solid materials in a manner that brings the metal closer towards what is called its equilibrium state. The heating process provide the energy needed for the atoms to break their bonds and hence eventually allow metals to be more amenable to deformation or ductile in nature.There are three stages of this process with the first one being the phase in which softening of the metal occurs through the removal of crystal defects and dislocations and internal stresses. This phase covers the entire process before new grains are formed that are free from pre-annealment process stress. The second phase is the one in which new grains are formed to replace the ones that were deformed by stress. The third phase is when the process is allowed to carry on once the formation of new crystals has been completed and a new phenomena called grain growth occurs that may cause the annealed alloy or metal to have unwanted mechanical and strength characteristics.

Annealing is a heat treatment procedure by which we can make changes to a material by causing changes in its specific properties such as hardness and strength of the material. This process can be implied on the materials such as steel, silver, copper and brass and is performed by considerably heating the material for a specific time period and then it’s allowed to cool. The machinability requirements of steel are different and thus, this process is used to enhance the properties of steel to meet the specific requirements. In case of steel, it is heated to 723 degrees Centigrade of temperature, after which it is allowed to cool. Stages of the Procedure:The process is conducted under three stages:Recovery Phase RecrystallizationGrain GrowthThe environment which is required for this process to occur is extremely decisive as during the procedure, the material needs a carbon rich atmosphere facilitating carburization. Types of this Heat Treatment Process:Various types of this heat treatment process are available:1.Process Annealing2.Full Annealing3.Stress Relief4.Isothermal 5.Spherodise The first method of the heat treatment process generally suits for low carbon steel and is mainly passed on cold rolled steel such as wire drawn steel etc. This method tends to improve the characteristics such as ductility and hardness which otherwise makes the process difficult. In the second method, the steel involves heating to about 30 to 50 degrees centigrade above a significant temperature of the material. The temperature is then holed for a specified time period and then inside a furnace the material is allowed to cool without any forced ways of cooling. This process can be applied to: castings made from high carbon and medium steels, hot worked sheets and forgings etc.The Stress Relief process can be used for large welded structures and castings. High carbon and alloy steel uses the Spherodise method and isothermal procedure is mainly appropriate for alloy steels and for low carbon. Setup and Equipment:For this process of heat treatment, special large ovens are used which are huge enough to store the work piece in the right position in order to get maximum exposure to the heated air in the oven. Special gas fired conveyor furnaces are mainly used for high volume process annealing. Carbon bottom furnaces are used for especially for high quality parts or for large work pieces. Once the process is completed, these work pieces are often quickly cooled. After crossing all these stages, here are some defined benefits of this particular heat treatment process. Advantages:Some advantages of this heat treatment process are mentioned below:1.Improves and enhances the machinability of the steel2.The ductility of the steel can be increased3.The steel is softened by the procedure4.It augments the toughness of the steel5.The homogeneity of the steel can be enhanced6.It refines the grain size of the steel7.It further prepares the material for other heat treatment.

There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire industry and has benefited various other industries across the globe. This heat treatment procedure has helped in enhancing the quality of steel used across the world. It is one of the significant contributions that have taken place in the field of science.It is a procedure to enhance the machinability of steel. Through this process, steel is heated to a temperature of 723 degrees Centigrade after which it is left for cooling. There are five types of Annealing: Full, Process, Stress Relief, Spherodise, and Isothermal. The ideal temperature for the annealing process is generally a temperature, which is selected between the higher and the lower end of a particular range. However, the important part is that you keep the temperature steady for a certain period. In the annealing process, when the glass is in a particular temperature for a specific span of time it is known as soaking. When the glass is soaked in a greater temperature then the benefit is that it needs a shorter time span for the stress to dissolve. However, sometimes it may distort under the pressure of heat. It will need longer time to cool down than it would have taken when annealed at a temperature, which is much lower. Some of the basic advantages of this efficient process that one should be aware of are as follows: This procedure helps to augment the toughness in steel and increase its ductility. It helps to soften the steel and develop homogeneity of the material. Lastly, the steel is prepared in such a way it is geared up for advance heat treatment. Besides this, there are other heat treatment process that one can avail they are Stress relieving, Case hardening, Carburising, Homogenising, Carbonitriding, Shot Blasting, Induction hardening, and Tempering. The environment, which is required for the process is extremely critical. When steel is being annealed, it needs a carbon-rich environment that facilitates carburization. However, if you are to avoid such defects then this procedure is ought to be carried out in an environment that is completely devoid of any such elements. There are many companies in the market, which provide heat treatment processes at an extremely affordable price. Nevertheless, one must always go for the reputed ones and which has years of experience in this concerned field. For detailed information regarding such companies, you can refer the Internet. The Internet will provide you with all the relevant information, review, and comments, regarding this effective heat treatment process, which will help you to make the correct decision. It is better to find out more on this issue before you choose any particular company for annealing process of treatment. It is one of the most popular and effective forms of heating and hence widely used.

Annealing is a process by, which heating steel and holding it at a particular temperature and consequently cooling it at specific rate with the aim of enhancing the cold working aspects, softness, by removing the stress and getting a required structure. Generally the process is that the steel is heated to a particular temperature at, which the carbide is fully or partially taken into solution, and consequently the steel is gradually cooled and normally in the furnace. The process helps to alter a material and cause changes in properties like hardness and strength. The process is utilised to bring on elasticity, ease the internal stresses, soften material and distil the construction by enhancing the cold working aspects and making it homogenous. In cases of brass, copper, silver and steel the procedure is conducted by considerably heating the metal until its glows for some time and letting it cool. In contrast to ferrous metals that must be slowly cooled to anneal the above mentioned materials can be slowly cooled in space or by quenching them quickly in water. By this process the material is made soft and made for additional work like forming stamping and shaping. Annealing takes place by the dispersion of atoms inside a solid matter. So, the materials go ahead towards its balance condition. Heat is required to boost the diffusion rate by giving the energy requiring required to sever bonds. The atoms movements have the result of reallocating and annihilating the displacement in materials. This change in dislocation lets metals to distort more easily that enhance their ductility. The internal stress relief is a thermo-dynamically impulsive procedure, although at room temperatures. The procedure is very slow. The elevated temperatures at, which the procedure takes place serve to speed up the procedure. There are 3 basic stages of annealing. The first is the recovery phase, second being the re-crystallization and lastly the grain growth takes places. In the first phase where softening takes place of the material via the crystal defects elimination and the internal stresses that they cause. In the 2nd phase innovative without strain grain nucleates and develops to put back those distorted through internal stresses. If the process is sanctioned to prolong the re-crystallisation will be completed and the growth of grain will take place in, which micro-structure commences to toughen and might source the metal to have fewer than suitable mechanical properties. The elevated temperature of this annealing process might end in material’s surface oxidation consequently in scale. The process is conducted in a particular atmosphere. If you are looking for companies that focuses on these heat treatment process then you will surely find quite a few of them. You just have to use your discretion to choose the most reliable and suitable one for yourself so that the decision of choosing it can benefit your business.

induction annealing

PDF: What Is Annealing

Hot

Relationship between induction frequency and quenching depth (hardening depth)

waveform of DSP induction heaters

simulation of Faradays Law from University of Colorado Boulder

optimizing induction welding method for vehicle air conditioner

induction welding vehicle air conditioner vs common welding method

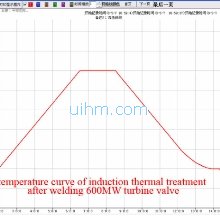

temperature curve of induction thermal treatment after welding 600MW turbine valve

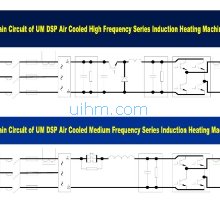

Main Circuit of UM DSP air cooled induction heaters

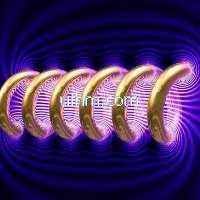

what is skin effect principle (magnetic force around induction coil)

Newest Comment

No Comment

Post Comment