Induction surface hardening

Views Send Enquiry

Kelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: An Analytical Approach including Magnetic Losses

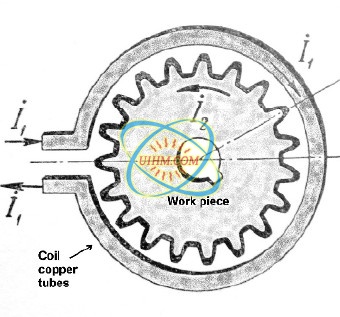

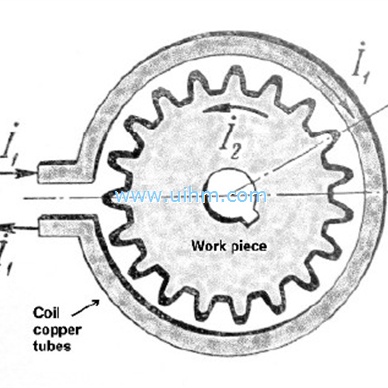

Abstract– Kelvin effect(Skin effect) is used in surface hardening produced by induction heating of gears, cam forms, camshafts and other work pieces of fairly complex geometries. The induction heating equipment for surface hardening of metals and alloys using LF (medium frequencies in the jargon of induction heating) is composed by a coil or coil assembly and a power semiconductor driving system up to 50 kHz. The load seen by the driving system is equivalent to a transformer.

The primary corresponds to the excitation coil or coil assembly, and the work piece corresponds to a short-circuited secondary. In these and others technical applications of Kelvin effect it is often necessary to be able to relate local skin depths with local curvatures of the surface of electrically conductive bodies. It was proposed recently a closed form analytical formula that relates the local skin depth with the local mean curvature and the well known skin depth for a flat conductive but non ferromagnetic body. The purpose of this paper is threefold. First, improve and give a critical discussion of the derivation of the aforementioned analytical formula. Second, generalize it to bodies with magnetic hysteresis losses. Third, apply the above mentioned generalized formula to describe the electrical load seen by the driving system in the conditions used for surface hardening.

The formulae given here could be applied to asses some characteristics of the load that may be of interest in the choice or design of the driving system, including the planning of digital simulations using complex computer codes. Index Terms–Induction heating, Load impedance modeling, Skin effect, Mean curvature, Hysteresis losses.

surface hardening

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction hardening surface of steel plate

induction hardening gear surface

induction hardening wheel gears

induction hardening TCT knife (tungsten carbide tool)

induction hardening knife edge (sickle blade)

induction hardening inner surface of steel pipe

induction hardening inner surface of steel ring by UHF induction heater

induction hardening inner surface of gear

Newest Comment

No Comment

Post Comment