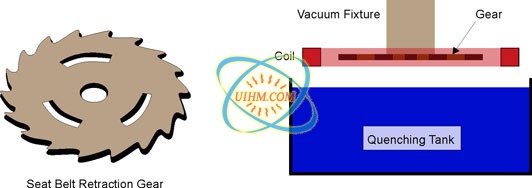

Induction hardening belt retraction gear

Views Send Enquiry

Objective Heat the teeth of a soft steel seatbelt retraction gear to 1700°F (926.7ºC) within two seconds for hardening.

Material #4130 steel seatbelt retraction gears, water vortex quenching tank, electronically controlled air valves, adjustable timers

Temperature 1700 °F(926.7ºC)

Frequency 165 kHz

Equipment • Power of 25kW induction heating system equipped with a remote workhead with 1.0 μF capacitance

• An induction heating coil designed and developed specifically for this application.

Process A four-turn helical concentrating coil is specially designed to deliver uniform heat to the steel seatbelt retraction gear. The parts are positioned in the coil above the quenching tank and held in place with a vacuum rosette fixture. Power is applied for two seconds to heat the part. The parts are then expelled

into the quench tank for cooling.

Results/Benefits Induction heating provides:

• Uniform and repeatable results

• Energy efficient

• Non-contact heating

Related Content

induction brazing SS steel by handheld induction coil

induction melting silicon and steel

magnesium oxide acidic furnace for induction melting glass

induction preheating gas pipeline by full air cooled clamp induction coil and DSP induction heater

induction melting with Titanium alloy pot by customized induction coil

induction melting aluminium for casting wire wheel

induction heating steel plate by pancake induction coil

induction heating steel knife

Hot

induction hardening surface of steel plate

induction hardening gear surface

induction hardening wheel gears

induction hardening TCT knife (tungsten carbide tool)

induction hardening knife edge (sickle blade)

induction hardening inner surface of steel pipe

induction hardening inner surface of steel ring by UHF induction heater

induction hardening inner surface of gear

Newest Comment

No Comment

Post Comment