Induction Curing adhesive

Views Send Enquiry

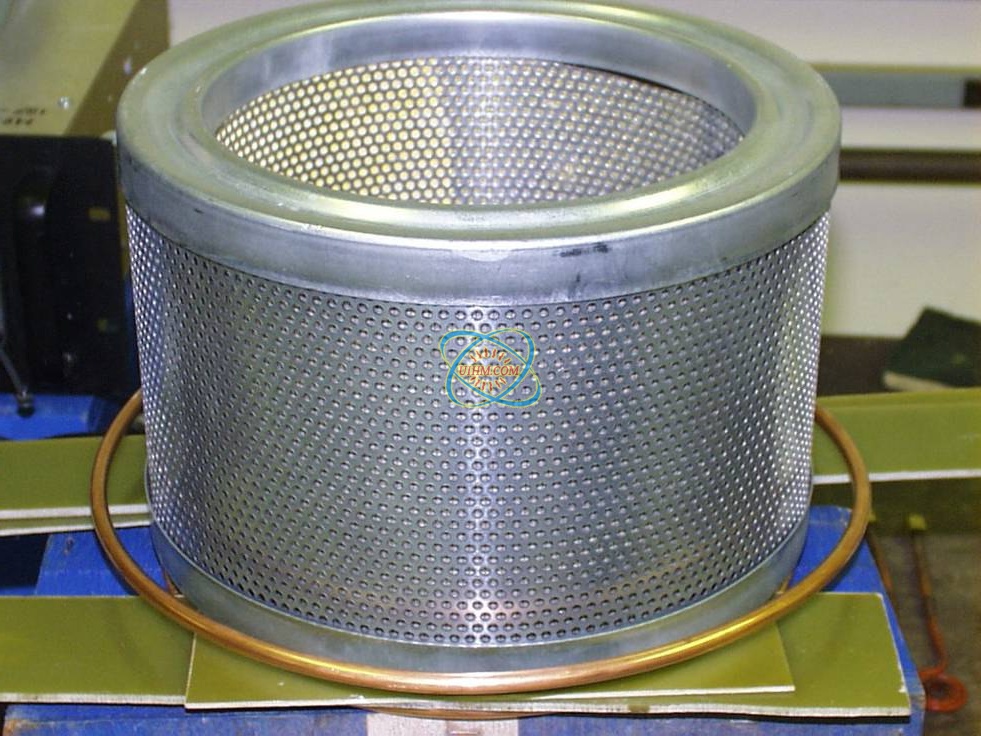

Objective To Cure adhesive in aluminum filter ends

Material Aluminum filter, steel end caps & plastisol adhesive

Temperature 200 ºF

Frequency 277 kHz

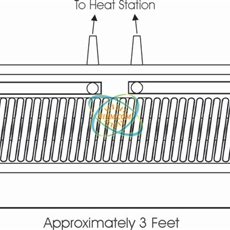

Equipment · Power of 6kW induction heating system, equipped with a remote workhead containing two 0.1uF capacitors for a total of 0.2uF

· An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Results/Benefits Induction heating provides:

· Faster curing times, increased production

· Reduced energy cost

· Localized heating, no damage to adjoining components

· Decreased production losses (reduction of downtime and scrap)

· Reliable, repeatable heat

Material Aluminum filter, steel end caps & plastisol adhesive

Temperature 200 ºF

Frequency 277 kHz

Equipment · Power of 6kW induction heating system, equipped with a remote workhead containing two 0.1uF capacitors for a total of 0.2uF

· An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil is used to cure the plastisol adhesive. One filter end cap is filled with adhesive, attached to the filter and heated 90 seconds to cure the adhesive. The filter assembly is then flipped; the second end cap is filled with adhesive and applied to the filter. Heat is applied to that end cap for 90 seconds to cure the adhesive. A second coil is recommended to heat 2 parts at once which would reduce the heat time to 45 seconds per part. The heat time can be further reduced by increasing the number of power supplies and coils.

Results/Benefits Induction heating provides:

· Faster curing times, increased production

· Reduced energy cost

· Localized heating, no damage to adjoining components

· Decreased production losses (reduction of downtime and scrap)

· Reliable, repeatable heat

Curing-plastisol-adhesive

Next: Induction curing coatingPrevious: Induction Curing Ceramic Fiber

Good

Bad

Hot

induction painting after induction bending for pipelines

induction heating steel plate

induction remove copper from aluminium

induction heating stator frame

induction heating graphite mould

difference between induction heating inner surface and outside surface of steel ring

induction heating steel pot bottom

induction heating for heat preservation

Newest Comment

No Comment

Post Comment