Research the heating effects

Views Send Enquiry

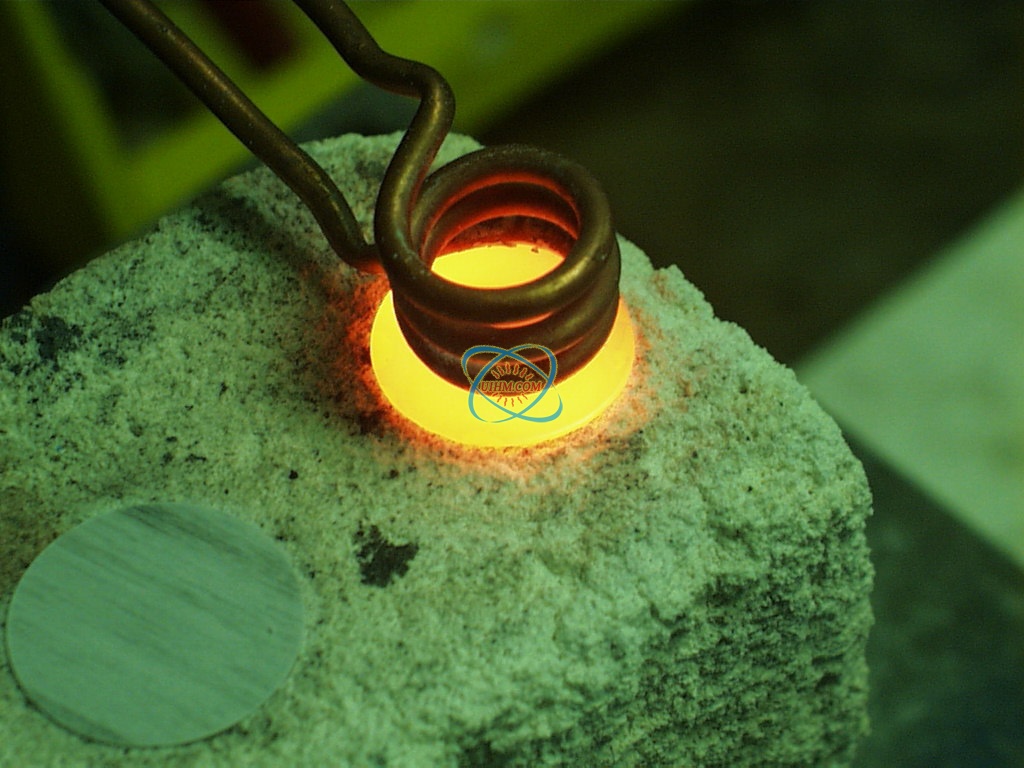

Objective Heating stainless steel disc & tantalum disc to 1400ºF (760ºC)

Material Stainless steel and tantalum discs approx 1/2” (12.7mm) diameter. End product is radioactivity counting plate

Temperature 1400 ºF (760ºC)

Frequency 350 kHz

Equipment •Power of 3kW induction heating system, equipped with a remote workhead containing one 0.66μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A three turn helical coil is used to heat the discs to 1400 ºF (760ºC). The stainless steel disc reaches temperature in 3.5 seconds, the tantalum disc reaches temperature in 1.7 seconds. The heat up time can also be varied by changing the

distance between the coil and the part to suit the application fixturing design.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Precise even heat without out the use of flame or oven

Research the heating effects

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction heating bolts from turbine

induction debonding from steel rod

induction debonding rubber

Releasing Fixture by Induction Heating

Remove plastic coating from steel tubes by Induction Heating

Induction Heating catheter tipping die

Induction Molding for teflon catheter tip

induction melting for crystal growth

Newest Comment

No Comment

Post Comment