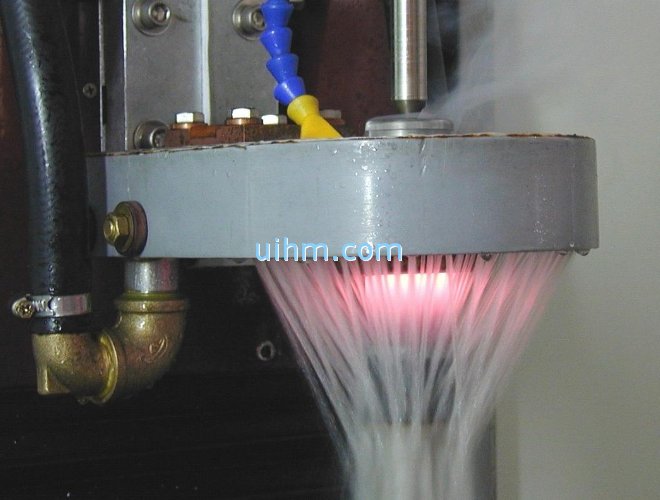

induction quenching with custom-design inductor

Views Send Enquiry

Induction quenching is a form of heat treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction quenching is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole.

induction quenching with custom-design inductor

Next: Induction Quenching PlugPrevious: induction melting aluminium

Good

Bad

Related Content

induction quenching surface

induction melting steel by custom-design 120KW induction heater

induction quenching head and end part of steel rod (axle)

induction quenching axle (shaft) by 160KW induction heater

induction installation (shrink fitting) couplings for Shaft Collar with flexible induction coil

induction quenching gear teeth

induction quenching axle

induction quenching axle (shaft)

Hot

induction quenching surface

induction quenching head and end part of steel rod (axle)

induction quenching gear teeth

induction quenching axle

induction quenching axle (shaft)

induction quenching axle (shaft) by 120KW induction heater (UM-120AB-HF)

induction quenching gear by 80KW induction heater (UM-80AB-HF)

induction quenching axle (shaft)

Newest Comment

No Comment

Post Comment