Induction heating for Plastic Reflow With Catheter Tubing

Views Send Enquiry

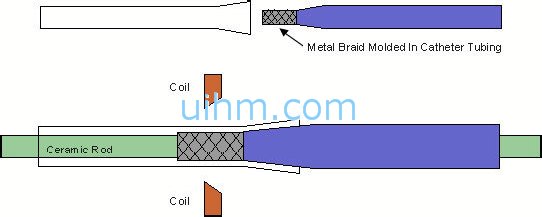

Objective Heat a metal braid in a plastic catheter tube to 250°F (121.1ºC) so that another catheter tube can be bonded to it.

Material 0.05” (1.27mm)diameter catheter tubes, some with a metal braid, ceramic rod

Temperature 250°F(121.1ºC)

Frequency 306kHz

Equipment 6KW induction heating system equipped with a remote workhead with one 1.2 μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A single turn helical coil is used to heat the metal braid for plastic reflow. To maintain the correct inside diameter of the tubing. A ceramic rod is inserted through the tubing. Heat is applied for 3.5 seconds to reach 250°F (121.1ºC). The metal braid melts the plastic and creates a bond.

Results/Benefits Induction heating provides:

• Controlled rapid application of heat

• Consistent, repeatable results

• Energy efficient

PDF: Induction heating for Plastic Reflow With Catheter Tubing

Good

Bad

Related Content

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating bolts from turbine

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

Hot

induction heating bolt

induction heating steel rod by UM-40AB-HF

induction heating end of pipeline by 160kw induction heater

induction heating steel plates by auto feed system with 120KW induction heater

induction heating cambered work-piece by 160KW power supply

U shape induction coil for heating hole

induction heating steel rod with double coils

induction heating steel mould

Newest Comment

No Comment

Post Comment